|

| |

TM 5-4210-220-34

3-8.

ENGINE - Continued

3-8.11

Cylinder Block - Continued

(5) Drill four 1/8 in. holes in saddle 1/4 in.

deep using predrilled holes in insert as a

guide.

WARNING

Death or serious injury could occur if

compressed air is directed against the

skin. Do not use compressed air for

cleaning or drying unless the pressure

is/has been reduced to 30 psi (2.11

kg/cm2) or less. When working with

compressed air always use chip guards,

eye

protection

and

other

personal

protective equipment.

(6) Use compressed air to clean drilled holes.

(7) Install rivets, being careful not to strike

insert. Rivets are used only for locating

insert; the bearing cap holds insert in place.

File of any excess rivet material.

(8) Remove hold down bolts and retaining

plates. File any excess material from insert

to make flush with the saddle cap.

(9) Install unfinished new undersize service cap

on repaired saddle. Tighten to 240 ft lb

(325 Nm).

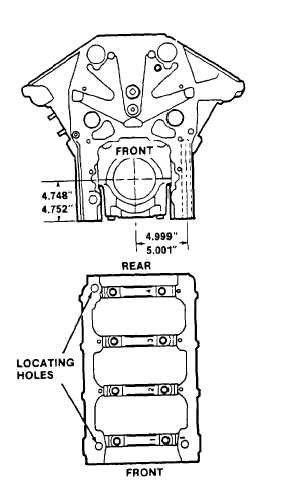

(10) Line bore the unfinished cap and insert to

standard bore dimensions of 4.812 4.813

in. (122.22 - 122.25 mm).

(11) Check finished bore with ’NO/GO’ test ring.

The ring should pass through the reworked

saddle and cap with a slight drag.

(12) If cylinder block line is properly bored, there

will be no more than 0.001 in. (0.03 mm)

overall misalinement from one end of block

to other, or 0.0005 in. (0.013 mm) between

adjacent bores.

(13) Thoroughly clean block.

3-194

|