|

| |

TM 5-4210-220-34

(5)

Use hone J5902-1 equipped with 120 grit stones. Spin hone at 300 - 400 rpm working the full length of liner a

few times to produce a criss-cross pattern having marks on a 45 deg axis.

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard’s solvent) is potentially dangerous. Avoid repeated and

prolonged breathing of vapors and skin contact with the liquid. Do not use near open flame, arcing

equipment or other ignition sources. Always wear eye protection and protective clothing. The flash point of

P-D-680 is 100 to 138 deg. F (30 to 59 deg. C).

Death or serious injury could occur is compressed air is directed against the skin. Do not use compressed

air for cleaning for drying unless the pressure Is/has been reduced to 30 psi (2.11 kg/cm2) or less. When

working with compressed air always use chip guards, eye protection and other personal protective

equipment.

(6)

After honing the liner remove it from the holding fixture and clean it thoroughly with dry cleaning solvent (item

10, Appendix B). Blow dry with compressed air

NOTE

A reused liner must conform to the same

limits on taper and out-of-round as a new

liner.

(7)

With

liner

secured

in

holding

fixture

measure the inside diameter at various

points using cylinder bore gage J5347-B

and master ring gage J24564.

(8)

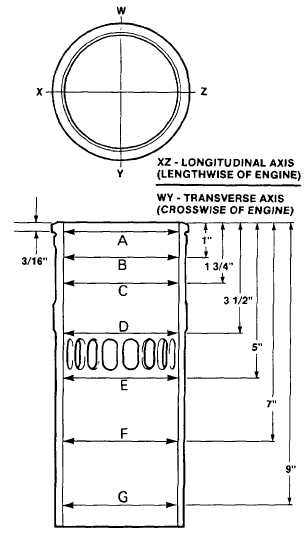

Measure inside diameter of liner at points A,

B, C, D, E, F, and G on axis XZ and WY.

(9)

The taper and out-of-round of a used liner

must not exceed 0.0025 in. (0.0635 mm).

Taper on a new liner must not exceed

0.0015 in. (0.0381 mm). Out-of-round on a

new liner must not exceed 0.002 in.

(0.0508 mm).

(10)

Replace liners that do not meet required

specifications.

INSTALLATION

a.

Liner Installation

(1)

Be sure inside and outside of liner are

clean.

Make

sure

block

bore

and

counterbore are clean.

(2)

Clean seal ring grooves in block.

3-167

|