|

| |

TM 5-4210-220-34

3-8.

ENGINE - Continued

3-8.7

Gear Train - Continued

a.

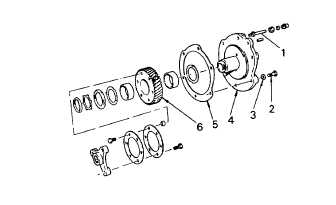

Blower Drive Gear Installation

NOTE

There are no timing marks on the blower drive

gear. Therefore it is not necessary to aline this

gear

in

any

particular

position

during

the

installation procedure.

(1)

Affix a new gasket (5) to the blower drive

gear support (4) and attach the gear and

support assembly to the cylinder block rear

end plate with capscrews (2) and copper

washers (3). Tighten the capscrews to 30 ft

lb (41 Nm).

(2)

ttach the lubrication line (1) to the blower

drive support (4).

(3)

Check the gear backlash between the blower drive gear (6) and the camshaft gear. To accurately check the

backlash, all of the flywheel housing attaching capscrews must be tightened to their proper torque, see para.

3-8.6. Backlash should be 0.002 0.008 in. (0.051 0.203 mm), and should not exceed 0.010 in. (0.254 mm).

(4)

Install the blower, see para. 3-8.3.

b.

Idler Gear Installation

(1)

Position the crankshaft gear and

the

camshaft gear so the timing marks will aline

with those on the idler gear.

(2)

With these marks aligned, start the idler

gear (5) into mesh with the crankshaft gear

and camshaft gear, and simultaneously

rotate the gear hub (3) so the dowel (4) in

the hub mates with the hole in the end

plate. Then, using a soft faced hammer,

gently tap the hub until it seats against the

end plate.

(3)

Secure the idler gear assembly to the

cylinder block using the special washers (2)

and bolt (1). Tighten the bolt to 90 ft lb (122

Nm).

(4)

Lubricate the idler gear bearing and gear teeth with engine oil (item 17, Appendix B).

(5)

After installation is complete, check the backlash between the mating gears. Allowable backlash for new

gears is 0.002 0.008 in. (0.051 0.0203 mm). Backlash must not exceed 0.010 in. (0.254 mm) for worn

gears.

3-146

|