|

| |

TM 5-4210-220-34

3-8.

ENGINE - Continued

3-8.7

Gear Train - Continued

c.

Crankshaft Gear Removal

(1)

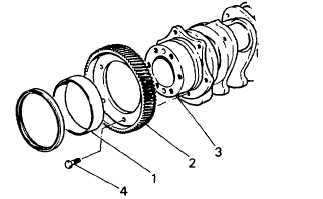

Remove the crankshaft rear oil sleeve (1), if

used. To remove the sleeve, peen the

outside diameter of the sleeve until It

stretches sufficiently so it can be slipped off

the crankshaft (3).

(2)

Remove the bolts (4) which secure the gear

(2) to the crankshaft (3)

(3)

Provide a base for the gear puller by placing

a steel plate across the cavity in the end of

the crankshaft (3).

(4)

Remove the crankshaft gear (2) using a

gear puller. Follow tool manufacturers

safety rules when pullers are used.

(5)

Examine the gear teeth for scoring, pitting or wear. If severely damaged or worn, install a new gear. Make

sure to carefully examine the other gears in the gear train.

d.

Camshaft Gear Removal

(1)

For camshaft gear removal, see para. 3-8.8 Camshafts.

INSPECTION

NOTE

This procedure may be used for any gear in the engine gear train.

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard’s solvent) is potentially dangerous. Avoid repeated and prolonged

breathing of vapors and skin contact with the liquid. Do not use near open flame, arcing equipment or other ignition

sources. Always wear eye protection and protective clothing. The flash point of P-D-680 is 100 to 138 deg. F (30 to

59 deg. C).

Death or serious injury could occur if compressed air is directed against the skin. Do not use compressed air for

cleaning or drying unless the pressure is/has been reduced to 30 psi (2.11 kg/cm2) or less. When working with

compressed air always use chip guards, eye protection, and other personal protective equipment.

(1)

Clean all of the parts with dry cleaning solvent (item 10, Appendix 8) and dry them with compressed air.

(2)

Examine the gears for chipped, pitted, burred or worn gear teeth. Replace gears as necessary.

3-144

|