|

| |

TM 5-4210-220-34

2-10.

PUMP BODY - Continued

2-10.1

Pump Body Assembly - Continued

NOTE

If the pump body is removed and

installed for the purpose of removing

hose body or agent tanks, disregard

steps (25 and 26) of this procedure and

steps (1 and 2) of the installation

procedure.

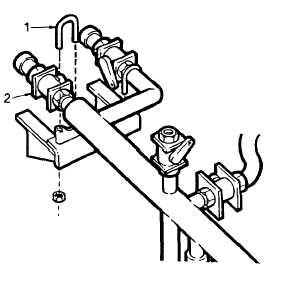

(25) Remove

four

clamps

(1)

attaching

discharge piping to pump body.

(26) Disassemble valves (2) (see TM 5-4210-

220-12) and remove discharge manifold,

valves, and discharge pipes from pump

body.

INSPECTION

(1)

Ensure that new pump body is free of

defects.

(2) Inspect structural control panel for damage and defects. Be sure wiring harness, and air and water lines are

free of defects and properly secured to control panel components.

(3) If control panel is replaced be sure the new panel is wired and plumbed identically to the one removed.

(4) Inspect discharge manifold and attaching components. Ensure that all items are undamaged and free of

defects.

INSTALLATION

(1) Position discharge manifold inside new pump body and assemble valves (2) (see TM 5-4210-220-12).

(2) Attach discharge manifold to pump body bracket using clamps (1).

(3) Attach lifting slings to pump body and hoist as in removal.

(4) Lift pump body onto truck carefully and aline mounting holes.

(5) Attach pump body to truck frame using four bolts and nuts. Remove lifting slings.

(6) Attach discharge manifold to pump discharge pipe using victualic coupling.

(7) Attach turret discharge pipe to manifold using victualic coupling.

(8) Thread hose reel heater hose up through body and attach to blower.

(9) Install PTO manual shutoff valve to left side of pump body. Install valve handle.

(10) Connect shop air line to air drier.

2-36

|