|

| |

TM 5-4210-220-34

3-7.

TRANSMISSION-Continued

(10)

Remove the carrier assembly from the press fixture. Install swaging tool holder J25587-17 into the

opening of the press fixture bed. Install a swaging tool J25587-21 into the holder. Install another swaging

tool J25587-21 into the press fixture ram. Lubricate both ends of the pinion pins with petroleum jelly (item

21, Appendix B).

(11)

Position the carrier assembly, rear end

upward on the press fixture. Use

support block J25587-3 to level the

carrier while the lower swaging tool is

supporting the lower end of one pinion

pin.

NOTE

Swaging pressure is approximately three tons for

each pinion pin. While applying pressure, rotate

pinions and feel for reduction of end play. The

pinions must rotate freely and have 0.008 in.

(0.20 mm) minimum end play after swaging the

pins.

(12)

Apply sufficient pressure to the press

fixture ram to firmly swage the ends of

the pinion pins against the metal of the

carrier.

(13)

Swage the remaining pinion pins.

ab.

Rear Planetary Gear Overhaul

(1)

Rear planetary gear overhaul requires

tools

J25587-1 Fixture

J25587-2 Pin Remover and Installer

Adapter

J25587-6 Pin Remover and Installer

Spacer

J25587-29 Pin Remover

J25587-7 (four) Loading Pin

J25587-47 (four) Guide Pins

J25587-31 Pin Installer

J25587-17 Swaging Tool Holder

J25587-21 (two) Swaging Tool

J25587-5 Spacer Block

(2)

Drill planetary pins drilled from rear side

of carrier. Place carrier assembly in

fixture with drilled pins up. Install pin

remover J25587-29 into fixture ram.

Place J25887-2 Adapter and J25587-6

Spacer.

(3)

In position press out four pins. Remove and keep four groups separate.

(4)

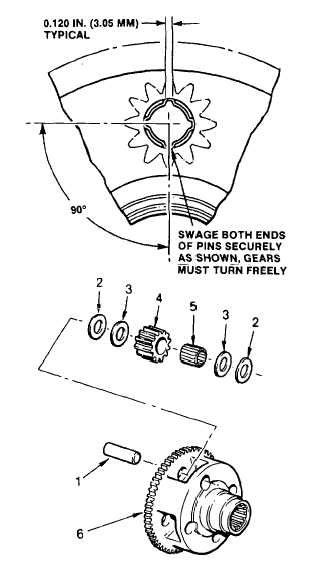

Inspect carrier (6) for excessive wear. Replace housing if damaged or worn excessively.

(5)

Install loading pin J25587-7 in each pinion (4). Install roller bearing (5) on pin then steel and bronze thrust

washers (2 and 3) on each end. Lubricate needle bearings with transmission fluid (item 9, Appendix B)

before installation of groups into carrier.

3-56

|