|

| |

TM 5-4210-220-34

3-7.

TRANSMISSION-Continued

(1)

Visually inspect planetary carrier assembly for evidence of excessive wear, overheat indication, damaged

or heavy metal contamination.

(2)

Tools required for rebuild are planetary rebuilding kit J25587-01 and a ten ton hydraulic press with an

adjustable bed of 25 in. minimum opening. The press must also have a pressure gage to correctly install

the pinion pins.

NOTE

Do not disassemble carrier assembly unless parts replacement is necessary. Failure of one pinion

requires replacement of the entire pinion gear set because they are selectively matched.

(3)

Check end play of planetary carrier pinions. With washer held flat, insert feeler gage between carrier and

thrust washer. End play must be within 0.008-0.031 in. (0.203-0.787 mm).

(4)

If planetary carrier requires overhaul, use a drill that is slightly smaller than the pinion pin diameter, drill

into the swaged ends of the pins (only one end required). Do not drill into the carrier. The rear ends of all

pinion pins except those in the center carrier assembly will be drilled. Drill the front ends of the center

assembly pins.

(5)

Place press fixture J25587-1 in hydraulic press. Select proper adaptors to perform removal or installation

operations on planetary to be overhauled.

(6)

Refer to para. z. for front planetary gear overhaul; para. aa. for center planetary gear overhaul; para. ab.

for rear planetary gear overhaul and para. ac. for low planetary gear overhaul.

z.

Front Planetary Gear Overhaul

(1)

Front planetary gear overhaul requires

tools

J25587-1 Fixture

J25587-16 Pin Remover

J25587-20 (six) Loading Pin

J25587-49 (six) Guide Pin

J25587-9 Pin Installer

J25587-17 Swaging Tool Holder

J25587-25 (two) Swaging Tool

J25587-4 Support Block

(2)

Drill out planetary pins from rear side of

carrier. Place carrier assembly in fixture

with drilled pins up, Install pin remover

J25587-16 into fixture ram.

(3)

Press out six pins. Remove and keep six groups separate.

(4)

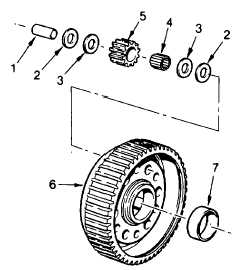

Inspect carrier (6) for loose or worn bushing (7). Replace housing carrier if damaged or worn excessively.

(5)

Install loading pin J25587-20 in each pinion (5). Install roller bearing (4) on pin, then steel and bronze

thrust washers (2 and 3) on each end. Lubricate needle bearings with transmission fluid (item 9, Appendix

B) before installation of groups into carrier.

3-53

|