|

| |

TM 5-4210-220-34

3-7.

TRANSMISSION - Continued

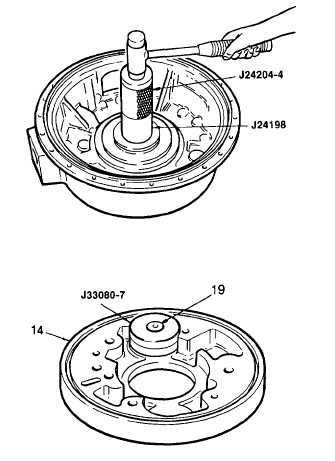

(10) Remove each driven gear shaft (19) (pump spindle) from the pump body, if necessary, using special tool set

J33080.

(11) Place puller assembly, puller bridge J33080-20 and collet J33080-4, over shaft to be removed with the legs of

the puller on the pump body.

(12) Tighten the collar locknut until collar is secured against collet and onto the shaft that is to be removed.

(13) Hold puller screw with wrench while tightening puller nut to remove shaft.

(14) To remove the shaft from collet, back off the collar locknut and puller nut. Position collar over retriever

J33080-2 and tap top of puller screw with a hammer to remove the shaft from the collet.

(15) Install new oil seal using seal installer J24198 , and driver handle J24204-4. Coat oil seal bore in pump body

with seal retainer (item 26, Appendix B). The lip of the seal must face inward (toward rear of transmission).

Seal should be flush with front of the housing

NOTE

Installer J24198 can be used with the

transmission assembled except for the

flywheel and torque converter.

(16) To install a new driven gear shaft (pump

spindle)

support

the

charging

pump

housing (14) in a press Position height

gage J33080-7 over the shaft bore and

place new shaft (19) into the gage so the

chamfer on the shaft will engage into the

housing bore.

(17) Press the shaft until flush with height gage.

The installed height of the spindle after

installation should be 0.926 - 0.885 in.

(23.52 - 22.48 mm).

(18) If needle bearing was removed from either

driven gear, install a new bearing. Place

the bearing, numbered end first, onto

installer tool J28646A. Attach handle

J8092. Install the bearing into driven gear.

(19) Install the driven gears (17) and the drive

gear

(20) into the oil pump body (14).

3-33

|