|

| |

TM 5-4210-220-34

2-21.

FRONT AXLE - Continued

2-21.2

Differential Carrier - Continued

(3)

Apply press load (see chart below) to the assembly and check rolling torque. Wrap soft wire around the

bearing cage, attach spring scale and pull. Preload is correct when torque required to rotate the pinion

bearing cage is from 10 20 in. lb (1.1 2.3 Nm). This specification is translated into spring scale readings in

the chart below.

(4)

If necessary, adjust pinion bearing preload by changing the pinion bearing spacer. A thicker spacer will

decrease preload. A thinner spacer will increase preload.

NOTE

Once correct bearing preload has been established, note the spacer size used. Select a spacer 0.001 in.

(0.03 mm) larger for use in the final pinion bearing cage assembly. The larger spacer compensates for

slight "growth" in the bearings which occurs when they are pressed on the pinion shank. The trial build-up

will result in proper pinion bearing preload in three of four cases. Do not assume that all assemblies will

retain proper preload once bearings are pressed on pinion shank. FINAL PRELOAD TEST MUST BE

MADE IN EVERY CASE.

Specifications for Pinion Bearing

Spring Scale Reading

Trial Build-up Preload Test

(without pinion seal)

Nominal Bearing

Spacer Thickness

Press Loads

in.

mm

Tons

Metric Tons

lbs.

kgs.

Front Axle

0.638

16.2

13.5-15.5

12.2-14.0

4-8

2-4

Rear Axle

0.496

12.6

17-19

15.4-17.2

3-7

2-3

d.

Pinion Bearing Preload - Final Test And Adjustment

NOTE

Rear axle pinion is equipped with helical

gear. For easier disassembly during

bearing adjustment procedure, use a

dummy yoke in place of helical gear.

(1)

Apply clamp load to the pinion bearing cage

assembly. Either install the yoke (or helical

gear) and torque the pinion nut to specifications

or use a press to simulate nut torque (see chart

below).

Vise Method - If the yoke and nut are used,

mount the assembly in a vise, clamping yoke

firmly.

Press Method - If a press is used, position a

sleeve or spacer so that load is applied directly

to the backface of the outer bearing cone.

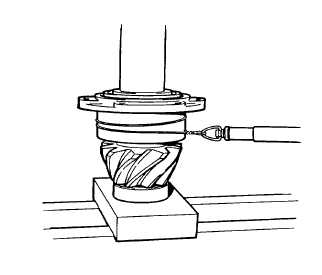

(2)

Measure pinion bearing preload by using a spring scale to test the assembly rolling torque.

To use the spring scale, wrap soft wire around the bearing cage, attach the scale and pull. Preload is correct

when torque required to rotate the pinion bearing cage is from 15 35 in. lb (1.7 4.0 Nm). This specification is

translated into spring scale readings in the chart below.

2-300

|