|

| |

TM 5-4210-220-34

2-21.

FRONT AXLE - Continued

2-21.2

Differential Carrier - Continued

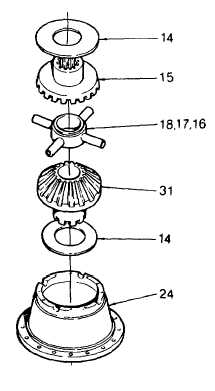

(16) Lift out spider (18) together with side

pinions (17), and thrust washers (16).

Remove inner side gear (31) and thrust

washer (14).

(17) Inspect inner and outer side gears and the

four side pinions. Replace all gears If

excessively

worn

or

damaged

teeth,

splines, or bearing surfaces are noticed on

any of the gears.

(18) Discard all thrust washers, (16 and 14) and

replace with new components. Inspect

thrust

washer

bearing

surfaces

in

differential case. Replace both halves as a

matched set if any surface is excessively

worn.

(19) Inspect differential bearings (9 and 22)

as detailed in para. 2-7. If replacement is

required, remove bearing cones from

differential case (20) and support cover (11)

using a suitable puller. Replace bearing

cups and cones in pairs.

NOTE

Prior to reassembly or installation, make sure all components are clean and coated with a film of

lubricating oil (item 17, Appendix B).

(20) If bearings are replaced, press new bearing cones (9 and 22) onto differential case (20) and support cover

(11). Be sure to use arbors that contact the bearing races only. Bearings may be damaged if pressure is

exerted on bearing roller cages.

(21) Install thrust washer (14), inner side gear (31), and spider (18) complete with side pinions (17) and thrust

washers (16) in support case (24).

(22) Install side gear (15), remaining thrust washer (14) and differential case (20). Make sure punch marks on

differential case and support case aline. Install capscrews (21) and tighten to 180 ft lb (245 Nm).

(23) Check free rotation of differential by turning side gear hub. Differential may require up to 50 ft lb (70 Nm)

torque to rotate.

NOTE

Front differential ring gear is attached with eight 3/4 in. 16 capscrews and locknuts. Rear differential ring

gear IS attached with sixteen 5/8 in. 18 capscrews and locknuts.

(24) Install ring gear (12) on differential support case (24) making sure bolt holes aline. A slight interference fit

may be present between the parts. If required, use a brass hammer to tap ring gear in place.

2-292

|