|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

(10) Clean and examine all components. Replace either spring if cracked, worn, or pitted. If the reason for

removal was failure of the governor to control the engine, replace both springs.

(11) Inspect the spring seats for wear or corrosion. Replace as required.

(12) Place the high speed spring (13) on the plunger (14) with the loosely wound end of the spring against the

shoulder of the plunger.

(13) Insert the spring and plunger assembly into the spring retainer (11).

(14) Place the adjusting pin (10) in the hole in the plunger. Thread the idle speed adjusting screw (9) into the

threaded end of the plunger (14) about 1/2 in. (13 mm).

(15) Thread the locknut (8) onto the idle speed adjusting screw (9).

(16) Place the low speed spring (16) in the low speed spring cap (17) and the small end of the low speed

spring seat (15) into the opposite end of the spring.

(17) Insert the low speed spring assembly into the plunger (14) and over the idle speed adjusting pin (10).

(18) Insert the spring, plunger, and retainer assembly into the opening in the governor housing and thread the

retainer (11) into the housing approximately 1 in. (25 mm). Be sure the locknut (12) is installed on the

retainer.

(19) Adjust the governor as detailed in ADJUSTMENT preceding.

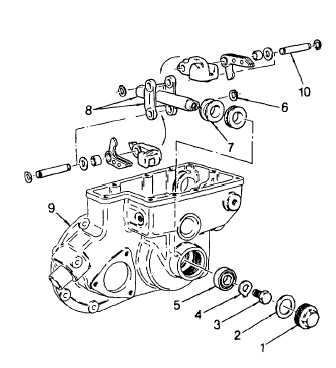

d.

Governor Weights and Bearing Repair

NOTE

Governor must be removed from engine

to carry out repair of the governor

weights and shaft assembly.

(1)

Remove governor from engine as

detailed in REMOVAL preceding.

(2)

Clamp the flange of the governor

housing (9) in a vise equipped with

soft jaws.

(3)

Unscrew and remove the plug (1) and

gasket (2). Discard the gasket.

(4)

Bend down the tang on the lockwasher

(4).

(5)

While preventing the weight carrier (8)

from turning, remove the bearing

retaining bolt (3), flat washer, and

lockwasher (4).

(6)

Thread a 5/16 - 24 X 3 in. bolt into the

bearing retaining bolt hole.

2-257

|