|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

2-19.7

Exhaust Valves.

This task covers:

a.

Adjustment

b.

Removal

c.

Inspection

d.

Installation

e.

Repair

TOOLS

Top Exhaust System Elbow Removed

Shop Equipment, Automotive

(see TM 5-4210-220-12)

Maintenance and Repair,

Both Rocker Covers Removed (see para. 2-19.3)

NSN 4910-00-754-0705

J22582 Engine Barring Tool

MATERIALS/PARTS

J7455 Valve/Spring Removal Tool

10, Appendix B Dry Cleaning Solvent

J9708-01 Feeler Gage

15, Appendix B Gear Oil

J22738-02 Spring Tester

17, Appendix B Engine Oil

J5437 Valve Guide Brush

18, Appendix B Masking Tape

J8932-01 Fuel Pipe Socket

5149510 Rocker Cover Gasket

J25076-B Spring Checking Gage

5147347 Exhaust Valve Spring

8921209 Exhaust Valve Guide Seal

5149041 Exhaust Valve Kit

EQUIPMENT CONDITION

Main Engine Shutdown (see TM 5-4210-220-12)

APU Shutdown (see TM 5-4210-220-12)

PERSONNEL REQUIRED - 2

Batteries Disconnected (TM 5-4210-220-12)

LH and RH Engine Covers Removed

(see TM 5-4210-220-12)

ADJUSTMENT

NOTE

This is the first task in any tune-up.

Exhaust valve bridge is adjusted during valve installation; the push rod only is adjusted after the engine is

rebuilt. Rocker must be removed as detailed in para. 2-19.3.

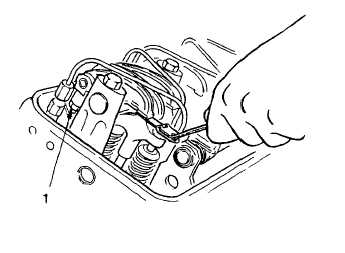

(1) Cover any drain cavities in cylinder head to

prevent foreign material entering.

(2) Allow engine to cool completely; must be

less than 100 deg. F (38 deg. C).

(3) Ensure governor speed control lever is in

the idle position and stop lever is in the stop

position. This is the normal setting when

engine is shutdown.

(4) Remove starter motor and install barring

tool J22582 (see TM 5-4210-220-12 for

starter motor removal) or barr engine using

starter motor or wrench on the crankshaft

pulley bolt (if using wrench, do not rotate

engine in left-hand direction because this

may loosen the bolt).

2-204

|