|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

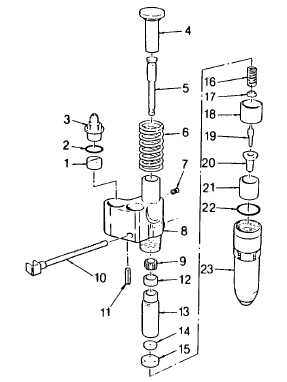

2-19.5

Injectors - Continued

(32) Rotate the Injector one complete turn and note

the total runout on the dial.

(33) If total runout exceeds 0.008 in. (0.20 mm)

remove the injector from the gage. Loosen the

injector nut, recenter the spray tip by rotating.

Then retighten nut to 75 ft lb (115 Nm) and

repeat the concentricity test. If the spray tip

cannot be repositioned, rebuild the injector

with a new nut.

(34) Perform tests a, c, and d detailed in TEST

preceding. The injector must pass all tests

prior to service. If it fails, repeat all

disassembly,

inspection,

and

assembly

instructions.

d.

Fuel Injector Tube Repair

NOTE

Injector tube cannot be repaired. If the tube leaks it should be replaced. Cylinder head must be removed

to carry out this task.

(1)

Remove cylinder head as detailed In para. 2-19-8.

(2)

Place the injector tube installer J5286-4B in the injector tube. Insert the pilot J5286-5 through the small

opening of the injector tube. Thread the pilot onto the installer. Handtighten the pilot.

(3)

Tap on the end of the pilot to loosen the injector tube then lift tube, installer, and pilot out of the cylinder

head.

(4)

Discard the tube and seal.

(5)

Thoroughly clean the injector tube holes in the cylinder head to remove dirt, burrs, or foreign material.

(6)

Carefully remove burrs and foreign material. Do not not scratch or dent the sealing surfaces.

NOTE

Any cylinder head resurfacing must be done prior to injector tube installation.

(7)

Lubricate the new injector tube seal with engine oil (item 17, Appendix B). Place in top counterbore of

cylinder head.

2-190

|