|

| |

TM 5-4210-220-12

Table 2-1. Operator Preventive Maintenance checks and Services (PMCS) - Continued

A - After Mission

D - Daily Checks

W - Weekly

Interval

Item

ITEM TO BE INSPECTED/Procedure

Equipment is not

No.

A

D

W

Ready/Available If

20

HOSE INSPECTION

Pull out hose reel hose to its full length. Inspect

- Hose missing or

hose for kinks, tears or cuts.

severely cut or kinked.

Report any failed hose to Organizational Maintenance

for repair.

21

HOSE CONNECTOR INSPECTION

With hose reel hose pulled out from reel, inspect

- Connector leaking or

each connector for damage/looseness. Tighten all

badly damaged.

connectors as required. Report any damage to

Organizational Maintenance for repair.

22

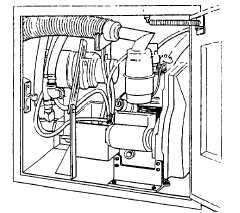

APU INSPECT

Open APU compartment door and check for oil leaks

and dirty engine cooling fins. Clean up as required.

Check all hoses for water/fuel leaks.

Check for corrosion/tightness of all electrical

connections.

Check alternator drive belt tension. Belt movement

should be less than 1/2 in (1 cm) midway between

he pulleys.

Report any oil, fuel, or water leak, corroded electrical

connection or loose belt to Organizational

Maintenance for repair.

2-29

|