|

| |

TM 5-4210-220-12

4-32. FRONT AXLE - Continued

ADJUSTMENT

(1) Block the rear wheels to prevent the truck

from moving while working on the front

axle.

(2) Jack affected wheel end up as detailed in

para. 4-9. Support raised wheel end on

maintenance trestle.

NOTE

Brake adjustment may be carried

out

with

front

wheel

either

removed or installed.

(3) Connect truck batteries and start engine.

Run engine until air system is at normal

pressure.

(4) Stop the engine and disconnect truck

batteries.

(5) Push locking sleeve (B) on slack adjuster

down

and

turn

adjustment

screw

(A)

clockwise until brake shoes are tight against

brake drum.

(6) Back off screw (A) approximately two turns,

10-12 flats on the screw head, until there is

no brake drag.

(7) Be sure locking sleeve (B) engages adjuster

screw (A) when adjustment is completed.

(8) To be sure brakes are free and without drag,

tap brake drum with a hammer and listen for

a clear ringing sound, or turn the wheel in

forward and reverse direction and check

that brake shoes do not rub against brake

drum.

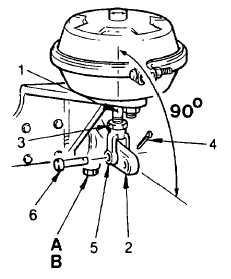

(9) Apply the brakes using the brake pedal in

the cab. Check the angle between air

chamber push rod (1) and slack adjuster

(2) as shown. The angle should be 90 deg.

(10) To adjust position of clevis, loosen jam nut

(3).

(11) Remove cotter pin (4) and disconnect

clevis (5) from slack adjuster by removing

pin (6).

(12) Turn clevis (5) as required to increase or

decrease overall length of push rod.

(13) Connect clevis (5) to slack adjuster (2) and

install clevis pin (6). Secure clevis pin

using cotter pin (4).

(14) Tighten jam nut (3) against clevis.

(15) Recheck angle between slack adjuster and

push rod as detailed in step 9 above.

(16) Repeat steps 2 thru 15 on second front

brake.

4-603

|