|

| |

TM 5-4210-220-12

4-32. FRONT AXLE - Continued

NOTE

If axle shaft assembly is removed for any reason

other than replacement, it should be thoroughly

inspected before reuse.

(5) Check shaft splines for damage, cracks, or wear.

Check shaft journal for scoring or excessive

grooving. Check that yoke trunnions are not

excessively loose in cage rings. Replace axle

shaft assembly if faulty or damaged.

(6) To measure exact clearance between axle yoke

trunnions and cage ring holes, the axle shaft may

be disassembled and the components checked as

detailed in steps 7 thru 10 following.

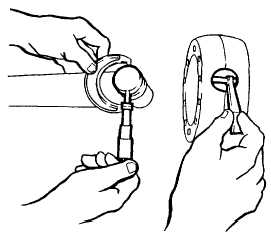

(7) Punch mark trunnions and cage rings as shown. To

ensure correct operation of axle shaft, the

trunnions must be replaced in the original cage ring

holes.

(8) Measure yoke trunnions and cage ring holes as

shown. If the clearance between corresponding

ring holes and yoke trunnions exceeds 0.050 in.

(1.25 mm) replace axle shaft assembly.

(9) If axle shaft assembly is reuseable, lubricate

journals with grease (item 16, Appendix E) and

reassemble components in exactly same positions

as before disassembly.

(10) Rotate the shaft and be sure the trunnions move

freely during a full revolution with the axle shafts

forming an angle of 30 deg.

(11) Be sure ball socket (4) is in straight ahead position

and grease axle shaft bushing. Pack inner walls of

axle ball with 3/4 in. (75 mm)! layer of grease (Item

16, Appendix E).

(12) Inspect axle shaft (5) and remove any nicks and

burrs to prevent damaging oil seal inside axle ball

when installing shaft assembly in housing.

(13) Carefully install axle shaft assembly. Be sure cage

rings are completely coated with grease when the

shaft is inserted in housing.

(14) Install brake spider (3) and spindle (2) using

capscrews (1). Tighten capscrews to 220 ft lb (300

Nm).

4-601

|