|

| |

TM 5-4210-220-12

4-32. FRONT AXLE - Continued

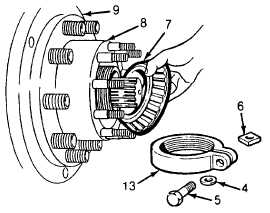

(3) Remove clamp screw (5) and lockwasher

(4) from wheel bearing adjusting nut (6).

This will release the nut lock Remove lock

(13) then unscrew and remove bearing

adjusting nut.

(4) Remove wheel outer bearing cone (7).

NOTE

If bearing cone is not to be

replaced identify its location so it

can be returned to its original

position.

Generally brake drum and hub may be left

assembled.

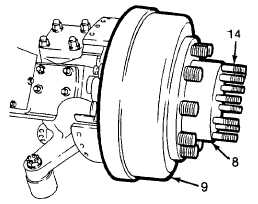

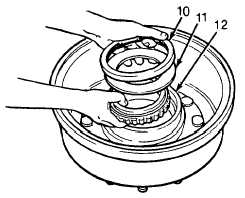

(5) Remove wheel hub (8), and drum (9)

assembled. To disassemble hub, remove

oil seal (10) and spacer (11) then lift out

inner bearing cone (12).

(6) Inspect bearing cones and cups for pitting,

wear or other faulty condition. If bearing

replacement is necessary, remove cup

from hub using suitable puller. Replace

bearings in sets (cup and cone).

(7) Inspect brake drum (9) for cracks,

discoloration due to hard spots, heat

checking, glazing, grooving or severe

out-of-round condition. Replace cracked

drums.

(8) Inspect hub (8) for damage. Replace hub if

faulty.

(9) If new hub is required, install new studs (14)

in hub. Apply antiseize compound (Item 3,

Appendix E) to studs before installation.

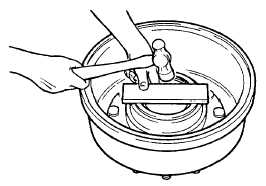

(10) If bearing cups were removed from hub,

install with suitable driver. Install cups until

they seat firmly against shoulder inside

hub.

(11 ) Line entire wall of hub with grease (Item

16, Appendix E). Fill hub with grease

leaving only an opening large enough for

the spindle to pass through.

(12) Pack bearing cones with grease (Item

16, Appendix E). Install inner bearing cone

(12) in hub. Install bearing spacer (11 ) on

cone with chamber (at inner diameter)

facing out.

(13) Install oil seal (10) in hub using suitable

driver or press. Press seal in until. It is

flush with face of hub.

4-597

|