|

| |

TM 5-4210-220-12

4-30. REAR AXLE - Continued

4-30.5 Air Shift Units - Continued

b.

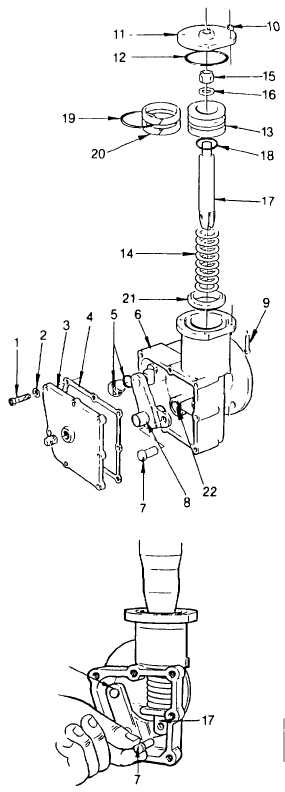

Differential Lock Air Shift Unit Repair Continued

(9)

Inspect housing and cover bearing bushings

(22). Replace bushings if these are heavily

worn or scored.

(10) Inspect piston (13). Replace if friction

surface

shows

excessive

wear,

deep

scoring, or other damage.

(11) Inspect push rod (17) and replace if thread

is stripped, clevis pin holes are elongated,

or rod otherwise damaged.

(12) In preparation for installation, soak new felt

oilers (20) in Dexron (item 9, Appendix E)

and lubricate O-rings (5, 12, and 19) with

petroleum jelly (item 27, Appendix E).

(13) Lubricate

bearing

bushings

(22)

with

Dexron (item 9, Appendix E) and install

actuating lever and pin (8), assembled as

shown, in shift unit housing.

(14) Install piston (13) and O-ring (18) on push

rod (17) and secure with washer (16) and

locknut (15). Tighten locknut to 150 in. lb

(17 Nm).

(15) Install felt oilers (20) and O-ring (19) on

piston (13).

(16) Insert piston stop (21), compression spring

(14) and the assembled piston and push rod

in shift unit housing. Be sure clevis end of

push rod (17) lines up with actuating lever

(8).

(17) Using a press, carefully push piston into

housing bore. As the push rod (17)

protrudes the spring stop bracket, make

sure push rod clevis straddles actuating

lever arm (8).

(18) Aline clevis pin holes in push rod and

actuating lever and install clevis pin (7).

(19) Apply gasket eliminator (item 14, Appendix

E) to capscrews (1).

4-580

|