|

| |

TM 5-4210-220-12

4-27. TRANSMISSION - Continued

(3)

Remove filter cartridge and discard.

(4)

Remove elbow fittings on filter base or transmission if fittings or O-rings are damaged.

(5)

Tag and remove hoses (4 and 5) to and from radiator cooler exchanger.

(6)

Place hoses on clean workbench area for complete cleaning and inspection.

(7)

If any hose was leaking or is found to be faulty during inspection refer to para. 4-9 to manufacture new

hose.

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard's solvent) is potentially dangerous. Avoid

repeated and prolonged breathing of vapors and skin contact with the liquid. Do not use near

open flame, arcing equipment or other ignition sources. Always wear eye protection and

protective clothing. The flash point of P-D-680 is 100 to 138 deg. F (30 to 59 deg. C).

(8)

If original hoses are to be reused, flush hoses thoroughly with dry cleaning solvent (item 10, Appendix E)

before installing.

(9)

Install filter and cooling hoses. Ensure there are no kinks or twists in hose assemblies. Be sure they are

at least 1 in. (2.5 cm) away from any moving or hot parts.

(10)

Lubricate filter seal ring with transmission oil (item 9, Appendix E) and install new filter cartridge.

Tighten filter 3/4 turn after filter seal contacts its seat.

(11)

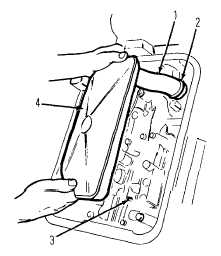

If transmission internal suction screen is to be inspected

and cleaned, remove 23 bolts that retain oil pan to

transmission housing. Discard pan gasket.

(12)

Remove suction screen retaining bolt, washer, and spacer.

Inspect screen (4) for damage. Replace or wash filter

screen assembly.

(13)

Install new seal ring (2) on intake pipe (1). Secure filter

assembly. Remove, clean, and reinstall governor feed line

screen (3) in valve body.

(14)

A sealer or cement (item 6, Appendix E) may be applied to

the pan flange area that is outside the raised bead of the

flange. Place new oil pan gasket onto the oil pan.

(15)

Install oil pan and gasket to transmission. Tighten screws to 13 ft lb (18 Nm).

(16)

Pour in approximately 55 qt (52 L) of new Dexron II (item 9, Appendix E). If during oil level check

procedure, inconsistent dipstick readings occur, look for improper venting of transmission breather.

Always check oil level on dipstick at least twice.

4-521

|