|

| |

TM 5-4210-220-12

4-26. DRIVE LINES, POWER TRAIN - Continued

REMOVAL

NOTE

Disconnect rear drive shafts and differential end of front drive shaft with the universal joint

crosses attached to shaft. Disconnect front drive shaft with U-joint cross to rear drive shaft

remaining attached to rear shaft.

a.

Drive Shaft Removal.

(1)

If the drive shaft universal joint locking screws and straps are corroded, apply penetrating oil (item 20,

Appendix E) to ease disassembly.

(2)

Mark all yokes and slip joints before removal. This will ensure alinement of components during installation.

(3)

Using a hammer and chisel bend down the ears on the two lockstraps (2) attached to the yoke opposite the

drive shaft to be removed (e g (7) in illustration).

(4)

Remove capscrews (1) and lockstraps (2).

CAUTION

Do not use jack method to

disassemble U-joint between front

and rear drive as this may cause

damage to the center bearing.

Unless special puller (Kent Moore

J36138) is available, disconnect

front and rear drive shafts at

differentials and detach center

bearing from frame. Disassemble

drive shafts on floor where shafts,

yokes, and center bearing can be

supported.

(5)

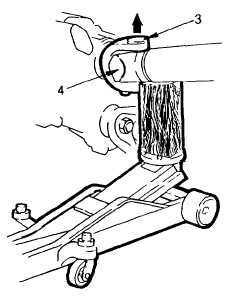

Turn the yoke until the bearing plates (3)

are vertically alined. If necessary, raise

the front or rear axle as detailed in para.

4-9.

(6)

Using a floor jack and a block of wood,

jack the wooden block up until it contacts

the drive shaft end yoke (4) as shown.

(7)

Continue to jack the block up until it

forces the upper bearing plate (3) out of

the yoke.

(8)

Once the upper bearing plate has been

removed, lower the jack and rotate the

shaft a half turn. Remove the second

bearing plate similar to steps 5, 6, and 7.

4-503

|