|

| |

TM 5-4210-220-12

4-22. AIR SYSTEM - Continued

4-22.12 Air Drier - Continued

REPAIR

a.

Safety Valve Repair

NOTE

Safety valve cannot be repaired, it must be replaced. It may be replaced with the drier

mounted on the truck. Ensure all air tanks are drained prior to safety valve repair.

(1)

Unscrew safety valve from elbow on side of drier and discard.

(2)

Coat new safety valve threads with pipe sealant (item 22, Appendix B) and screw onto elbow.

(3)

Test air drier as detailed in INSTALLATION, steps 5 thru 17, preceding.

b.

Check Valve Repair

NOTE

Check valve cannot be repaired, it must be replaced. It may be replaced with drier on truck.

Ensure all air tanks are drained prior to check valve repair

(1)

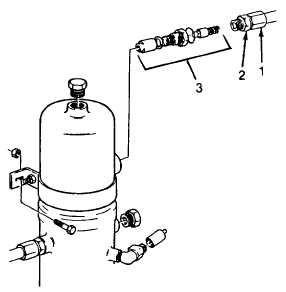

Remove outlet air line (1) from air drier

and remove outlet fitting (2).

(2)

Unscrew check valve (3) from air drier.

(3)

Coat threads of new check valve and air

line fitting with pipe sealant (item 23,

Appendix B). Be sure O-ring is on

external threaded portion of check valve.

(4)

Reinstall the check valve in the outlet port

and reconnect the air line.

(5)

Test

air

drier

as

detailed

in

INSTALLATION,

steps

5

thru

17,

preceding.

c.

End Cover Repair

NOTE

This may be repaired with drier on truck. Ensure all air tanks are drained prior to end cover

repair.

(1)

Tag and disconnect the air line from the end cover and mark location of this port on the drier.

4-382

|