|

| |

TM 5-4210-220-12

4-22 AIR SYSTEM - Continued

(3)

Ease valve body through cab floor.

(4)

Seal area around flange with sealant (item 25, Appendix E) and install screws (1) to secure valve to cab

floor.

(5)

Start main engine and ensure foot throttle provides increase in engine speed in proportion to treadle

depression. Ensure engine cuts back to low idle immediately treadle is released.

(6)

Stop main engine and disconnect batteries.

(7)

With treadle depressed about half way, brush soap solution over entire valve assembly and connectors.

No leakage is permitted. Tighten/remake joints as required. Ensure this bubble test is carried out with

primary air tank at greater than 65 psi (450 kPa).

REPAIR

a.

Treadle Repair

NOTE

This can be repaired without removing

whole foot throttle valve from truck.

(1)

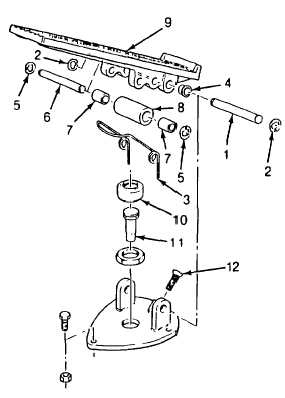

Remove spring clip (2), pin (1), pedal (9),

and spring (3).

(2)

Tap bushings (4) out of pedal.

(3)

Remove spring clip (5), pin (6), bushings

(7), and roller (8).

(4)

Remove dust boot (10) and push rod (11).

(5)

Inspect all parts for wear, or stiffness.

Replace any parts failing inspection.

NOTE

Item 1 thru 8 are available in the

repair kit. This kit also includes parts

to repair the valve subassembly.

(6)

Lubricate both pivot pins and push rod with silicone grease (item 27, Appendix E).

(7)

Install push rod (11) in valve. Install dust boot (10) over push rod. Be sure dust boot engages in housing

and on push rod.

(8)

Put bushings (7) in roller (8). Slide pin (6) through pedal and roller bushing and retain with clips (5).

(9)

Install bushings (4) in valve housing.

4-371

|