|

| |

TM 5-4210-220-12

4-22 AIR SYSTEM - Continued

(3)

Install air lines A, B, and C

(4)

Start main engine and allow all air tanks to fill with air

(5)

Brush valve body and connectors with soap solution. No leakage is permitted. Tighten/replace

connectors as required.

(6)

Shut down main engine and drain primary air tank (left rear wheel well)

(7)

Restart main engine while monitoring cab primary air pressure gage. Check that as soon as ignition

switch is operated and prior to engine start, the primary air tank is pressurized to at least 50 psi (340 kPa)

as a result of the air starter valve operating.

(8)

Replace front wheel and cab skid plate if required

REPAIR

NOTE

The air starter valve can only be repaired if it is removed from the truck. See REMOVAL

preceding.

(1)

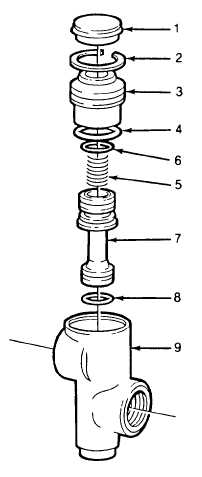

Pull off boot (1)

(2)

Push down on valve guide (3) and remove

retaining ring (2) Be aware that valve guide

is spring loaded

(3)

Remove valve guide (3) and push out

supply valve (7) and spring (5) from body

(9)

(4)

Remove and discard O-ring (4), supply

valve (7), retaining ring (2), and boot (1)

(5)

Clean

and

Inspect

all

remaining

components. Check for burrs, scuff marks

or

other

deterioration.

Replace

any

components failing inspection.

(6)

Coat all O-rings and sliding surfaces with

petroleum jelly (item 21, Appendix E).

(7)

Slide new supply valve (7) carefully into

body. Be sure lower O-ring (8) is not

scuffed as it passes the delivery port.

(8)

Install spring (5)

(9)

Install new O-ring (4) on valve guide (3)

and push carefully over supply valve and

into body. Retain with ring (2).

4-359

|