|

| |

TM 5-4210-220-12

1-12. ENGINE FUEL SYSTEM. - Continued

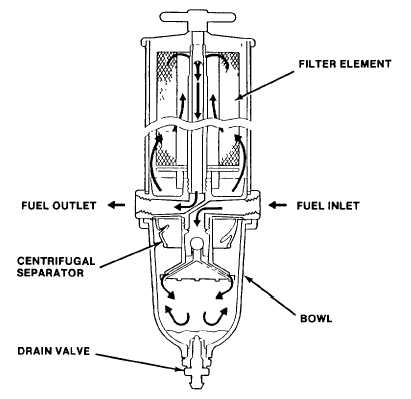

b. Fuel/Water Separator. The fuel entering the fuel/water separator is filtered in three stages. In. the first stage,

liquid and solid contamination up to 30 microns in size, is removed by centrifugal action in the lower part of the filter unit,

(see fig. 1-20). In the second stage, liquid contamination flows with the fuel into the filter separator shell. The liquid

contamination collects on the surface of the shell and on the replaceable element and forms drops. As these drops

become heavier, they fall to the bottom of the filter separator bowl. In the third stage, the fuel flows through the filter

element where minute solid particles are removed. The separator unit is equipped with a thermostat-controlled electric

disc heater. This heater is set to switch on when the temperature of the fuel drops below 35 deg. F (2 deg. C). When in

operation, the heater prevents formations of wax and thereby ensures a free fuel flow through the filter. The electric

circuit to the heater is controlled via the engine ignition switch.

NOTE

When the ambient temperature is below 35 deg. F (2 deg. C), the heater should always be on for a

few minutes prior to start-up to ensure that the fuel in the separator is clear.

Figure 1-20. Fuel/Water Separator

c. Engine Fuel Pump and Secondary Filter The fuel flowing from the fuel/water separator is delivered to the

engine-driven fuel pump. This pump is a gear-type unit which discharges the fuel at higher pressure to the secondary

fuel filter. In this filter, impurities that escaped filtration in the fuel/water separator are removed.

d. Fuel Injectors. From the secondary filter, the fuel flows to the engine injectors where it is metered and

atomized into the engine cylinders. Excess fuel is circulated around the injectors to cool them and returned to the tank

through the fuel return line and check valve. The check valve prevents system draining or back flow when the engine is

shut down.

1-27

|