|

| |

TM 5-4210-220-12

4-17. PUMP DRIVE AND PTO.

4-17.4 Reducer Gearbox Replace.

This task covers

a.

Removal

b.

Installation

TOOLS

MATERIALS/PARTS

Tool Kit, General Mechanic, Automotive,

3, Appendix E Antiseize Compound

NSN 5810-00-177-7033

15, Appendix E Gear Oil

20, Appendix E Penetrating Oil

EQUIPMENT CONDITION

200-A-2:1 Reducer Gearbox

Main Engine Shutdown (see para. 2-10)

MS51922-17 3/8 in. Locknut

APU Shutdown (see para. 2-12)

MS51922-9 5/16 in. Locknut

Batteries Disconnected (see para. 4-24)

Pump Body and Hose Body Heat Shield Removed

(see para. 4-11)

PTO to Reducer Gear Drive Shaft Removed

(see para. 4-17.2)

Reducer Gear to Pump Drive Shaft Removed

(see para. 4-17.3)

WARNING

Serious injury could occur if heavy equipment is moved/lifted without sufficient personnel to

do the job. Use proper physical lifting procedures or use a suitable lifting device or dolly.

Wear safety shoes, gloves and other suitable protective clothing.

CAUTION

Damage to reducer gearbox bearings may occur if the companion flange or end yoke are

forced onto the shafts. Ensure that the bores and shafts are free from dirt, paint, or corrosion.

Clean or repair as necessary.

NOTE

If the reducer gearbox fasteners are excessively corroded, apply penetrating oil (Item 20,

Appendix E) to ease disassembly.

REMOVAL

(1) Remove the drain plug and drain reducer

gearbox lubricant into clean drain pan.

Reducer gearbox lubricant should be warm

prior to draining. Inspect sediment on drain

plug. This may help determine component

condition before disassembly.

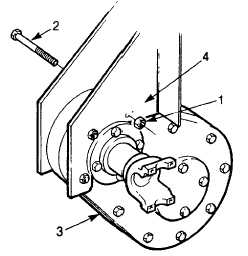

(2) Remove the locknuts (1) and capscrews (2)

that retain the reducer gearbox (3) to the

mounting brackets (4).

4-212

|