|

| |

TM 5-4210-220-12

4-15. AUXILIARY POWER UNIT - Continued

INSPECTION

(1)

Check crankshaft and camshafts for cracks using the Magnaflux method, or similar, see para. 4-9. Replace

components if cracks are detected.

(2)

Examine shaft gears for wear, replace shaft if

teeth are cracked or pitted.

(3)

Examine crankshaft main journals and crank pin

journal for seizure marks or grooves. Light

grooves can be removed with emery cloth (Item

13, Appendix E). Replace crankshaft if marks

are severe.

(4)

Measure crankshaft journal to crankcase cover

bearing in two directions at 90 deg. to each

other. Journal must be between 1.1028 -

1.1032 in. (27.90 - 28.00 mm). Replace

crankshaft if overworn. Journal cannot be

reground.

(5)

Measure main crankshaft journals in two

directions at 90 deg. to each other.

(6)

If any journal is more than 0.004 in. (0.10 mm) out of round, or total wear exceeds 0.004 in. (0.10 mm) replace

or regrind crankshaft to next undersize.

Crankshaft Journals

Nominal 1.5756 - 1.5760 in. (39.99 - 40.00 mm)

Diameter

1st undersize 1.5658 - 1.5662 in. (39.74 - 39.75 mm)

2nd undersize 1.5559 - 1.5563 in. (39.49 - 39.50)

Crankshaft Journal

Nominal 1.5772 - 1.5780 in. (40.03 - 40.05 mm)

Bearings Diameter

1st undersize 1.5673 - 1.5681 in. (39.78 - 39.80 mm)

2nd undersize 1.5575 - 1.5586 in. (39.53 - 39.55 mm)

Bearing to journal clearance at assembly should

be 0.0012 - 0.0024 in. (0.003 - 0.006 mm),

bearings are worn out if clearance exceeds

0.007 in. (0.17 mm).

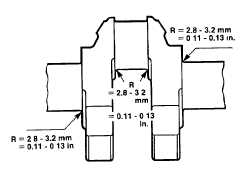

(7)

Restore journal fillet radius as illustrated. Do

not remove any material from journal flanges

facing side thrust washers.

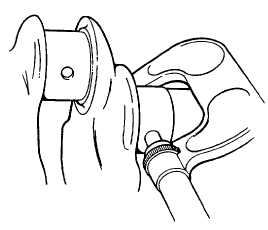

(8)

Remove expansion plugs from crankshaft and

clean out oil ways with wire

4-177

|