|

| |

TM 5-4210-220-12

4-15. AUXILIARY POWER UNIT - Continued

(13)

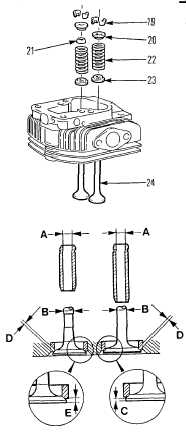

Compress each valve spring (22) in turn to

remove valve half cones (19), spring seats (20,

23) springs (22), oil seal (21) (intake only) and

valve (24).

INSPECTION

(1)

Remove all scale from cylinder head and valves

using a wire brush and scraper.

(2)

Inspect each rocker arm, if badly warn, scored

or damaged, replace.

(3)

Inspect rocker arm pivot, diameter must be

(0.370 - 0.378 in.) (9.4 - 9.6 mm). Clearance

between pivot and rocker arms(s) bore should

be less than 0.004 in. (0.1 mm).

(4)

Replace rocker arm(s) or pivot as required.

(5)

Check rocker arm lube holes are clear. Clean

out with stiff wire as required.

(6)

Inspect push rods and protecting tube. Push

rods should be straight with end tips smooth.

The protecting tube must be undamaged.

(7)

Discard upper and lower push rod cover seals.

(8)

Inspect valves it valve heads are distorted, cracked, mushroomed or seat surface are worn excessively

replace, (see table). If valves are only slightly worn regrind seat surface to 45 deg. on valve grinder.

B

A-B

C

D

E

in.

In.

In.

In.

In.

(mm)

(mm)

(mm)

(mm)

(mm)

0.275-0.276

0.001-0.003

0.028-0.035

0.055-0.063

0.063-0.071

(6.98-7.00)

(0.03-0.08)

(0.70-0.90)

(1.40-0.60)

(1.60-1.80)

4-163

|