|

| |

TM 5-4210-220-12

Table 2-1. Operator Preventive Maintenance checks and Services (PMCS) - Continued

A - After Mission

D - Daily Checks

W - Weekly

Interval

Item

ITEM TO BE INSPECTED/Procedure

Equipment is not

No.

A

D

W

Ready/Available If

35

AIR TANKS

Open draincock on each air tank and drain any water/oil

- Any air tank contains

out of the tank. When the air is free of spray, close

liquid water or oil.

draincock. If a stream of water/oil comes out of the

draincock, report to Organizational Maintenance.

Check tanks and fittings for any signs of leakage, serious

- Any air tank or hose is

dents or scratches. Report any deficiencies to

leaking.

Organizational Maintenance.

36

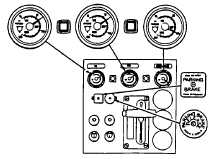

AIR SYSTEM

Check all air hoses, fittings and brake valves for signs

- Any air line is broken.

of leakage, serious dents, or scratches, cuts or

abrasions.

With the main engine running, operate the foot brake

- Air pressure in any

in the cab and ensure the brakes operate smoothly.

tank is less than 90 psi

Report any uneven or spongy action, dragging,

(620 kPa).

squealing, or chatter to Organizational Maintenance.

Check air pressure gages in cab register at least 90 psi

(620 kPa).

2-37

|