|

| |

unserviceable counterparts or remove and install

the same item when required for the performance

of other maintenance operation.

H-Repair: Restore to a serviceable condition by

replacing unserviceable parts or by any other

action required using available tools, equipment

and skills-to include welding, grinding, riveting,

straightening, adjusting and facing.

I-Overhaul: Restore an item to a completely serviceable

condition (as prescribed by serviceable standards

developed and published by the commodity

commands) by employing techniques of "Inspect

and

Repair

Only

As

Necessary"

(IROAN).

Maximum use of diagnostic and test equipment is

combined with minimum disassembly during

overhaul. "Overhaul" may be assigned to any

level of maintenance except organizational,

provided the time, tools, equipment, repair parts

authorization, and technical skills are available at

that level. Normally, overhaul as applied to end

items, is limited to depot maintenance level.

J-Rebuild: Restore to a condition comparable to new by

disassembling to determine the condition of each

component

part

and

reassembling

using

serviceable,

rebuilt,

or

new

assemblies,

subassemblies, and parts.

d.

Reference

Note.

Their

column,

subdivided into columns K and L, is provided for

referencing the Special Tool and Test Equipment

Requirements (sec. III) and remarks (sec. IV) that may

be associated with maintenance operations ( sec. II ) .

C-3. Explanation of Columns in Section III

a.

Reference Code. This column consists of a

number and a letter separated by a dash. The number

reference the T and TE requirements column on the

MAC. The letter represents the specific maintenance

operation the item is to be used with. The letter is

representative of columns A through J on the MAC.

b.

Maintenance Level. This column shows the

lowest level of maintenance authorized to use the

special tool or test equipment.

c.

Nomenclature. This column lists the name or

identification of the tool or test equipment.

d.

Tool

Number.

This

column

lists

the

manufacturer's code and part number, or Federal Stock

Number of tools and test equipment.

C-4. Explanation of Columns in Section IV

a.

Reference Code. This column consists of two

letters separated by a dash, both of which are

references to section II. The first letter references

column

L

and

the

second

letter

references

a

maintenance operation, columns A through J.

b.

Remarks.

This

column

lists

information

pertinent to the maintenance operation being performed,

as indicated on the MAC section II.

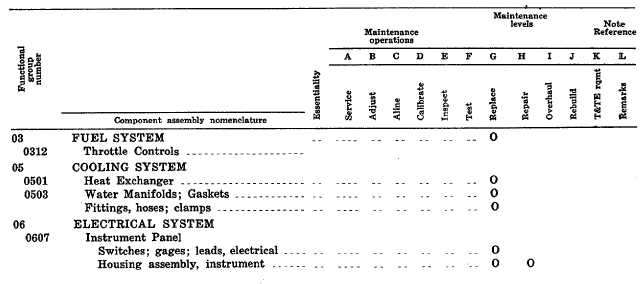

Section II. MAINTENANCE ALLOCATION CHART

C-2

|