|

| |

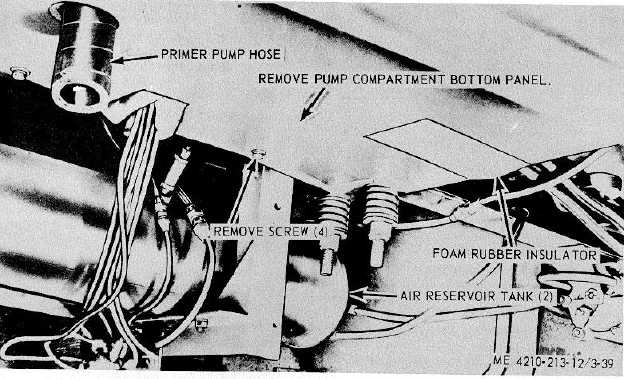

Figure 3-39. Pump compartment panel, removal and installation.

Section XlIl. PUMPING SYSTEM

3-86. General

The fire truck pumping system consists of a centrifugal

type pump rotary vacuum priming pump, steady valve,

relief valve; water tank, foam and two motor driven hose

reels. A series of operating valves, drain valve, and a

foam metering valve. Regulate operation of the fire

pump for pumping water, or a water and foam

combination. The centrifugal type pump develops

pressure and capacity, by means of centrifugal force,

and must be primed before it will lift water. The priming

system consists of a rotary vacuum pump operated by a

24-volt electric motor controlled through a manual

priming valve which activates a microswitch controlling

the electric motor. Water pressure is controlled

manually by a throttle knob and is held automatically by

a relief valve. The relief valve is adjusted to any pump

pressure up to 300 psi. The hose reels are electric

motor driven, and actuated by a reel rewind button,

located beneath the hose reel assemblies on the

instrument panel. The heat exchanger is mounted in the

engine

compartment, and circulates water through the engine

cooling system from the pumping system to cool the

engine. The primer oil tank is mounted on the engine

cab beneath the right hand seat. It supplies oil to the

primer pump.

3-87. Primer Pump

a.

Removal.

(1)

Remove the primer pump motor and

solenoid relay (para 3-71).

(2)

Refer to figure 3-40, and remove and

replace defective primer pump from the fire pump

manifold.

b.

Installation. Install the primer pump motor and

solenoid relay (para 3-71).

3-88. Hose Reel

a.

Removal.

(1)

Remove the hose reel motor solenoid

(para 3-68).

(2)

Remove the hose reel motor (para 3-69) -

(3)

Refer to figure 3-41, and remove the

3-55

|