|

| |

TM 10-4210-235-13

Location

Item

Item To Be

Procedure

Not Fully Mission Capable If:

No

Interval

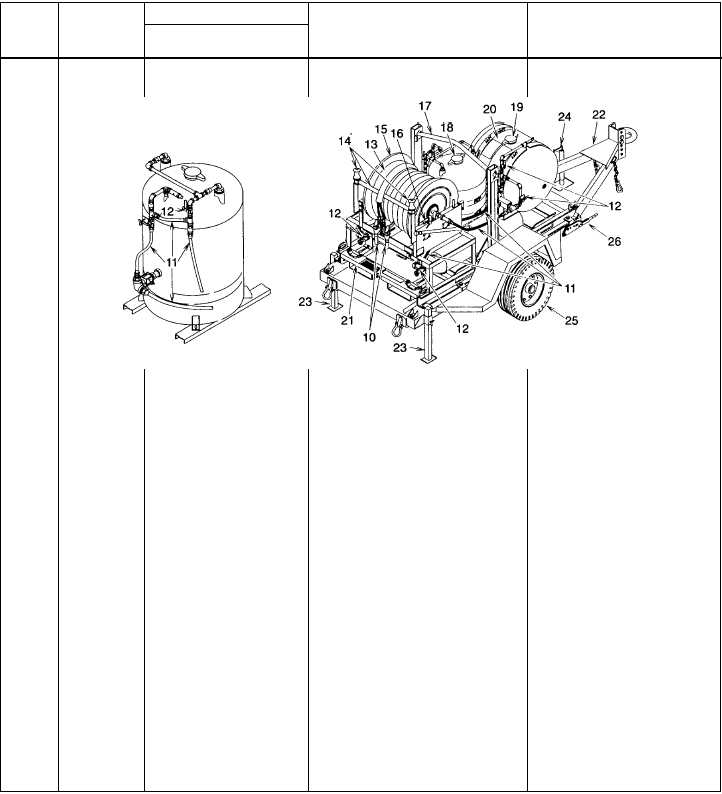

Check/Service

10

Before

Fire Hose Nozzle

Check for obstruction in fire hose

Fire hose nozzle is obstructed.

nozzle outlet.

Check that fire hose nozzle valve

Valve lever binds or is difficult to

levers squeeze smoothly with no

operate.

binding.

Notify your supervisor if

any gas escapes.

Be sure fire hose nozzle is secure on

nozzle bracket.

See paragraph 2-10.

11

Before

Hose Assemblies

Check that hose assemblies are

If any hose assembly shows

tight and in good condition with no

evidence of leakage, loose

evidence of leaking or dry rot.

connections, dry rot, or other

visible damage.

12

Before

Valves and Piping

Check for evidence of leaking or

Damaged, leaking, or strip ties

visible damage and if strip ties are

missing.

missing.

13

Before

Hose Assembly

Check that hose assembly is evenly

Hose assembly not evenly

wound on drum.

wound on drum.

Check visible portion of hose

If hose assembly shows

assembly to see if it is tight and in

evidence of leakage, loose

good condition with no evidence of

connections, dry rot or other

leaking or dry rot.

visible damage.

2-15

|