|

| |

TM 9-254

3-7.

Worm and Worm Gear Mechanisms - Continued

(4)

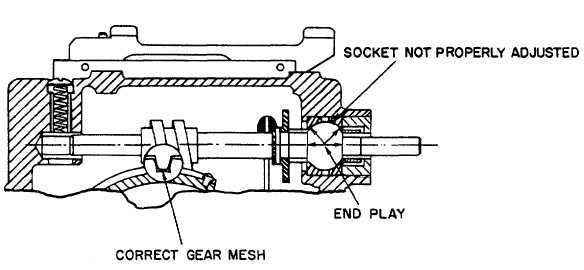

End play. End play is the term applied to lengthwise movement of a shaft (fig. 3-21). Such movement,

in a moderate degree, is acceptable when it does not contribute to the total backlash. Shafts are

normally restricted longitudinally by shoulders, collars, thrust bearings, ball caps, and sockets, or by a

combination of these. Seats, sockets, and wormshaft balls are commonly used for this purpose in

military instruments, the wormshaft ball being held between the seat and the socket. If the ball cap is

loose and the ball socket does not bear firmly and uniformly upon the ball, end play in the shaft will

result. As the wormshaft is rotated, the slack between the ball and seat or socket must be taken up

before the shaft will cause the worm gear to rotate.

Figure 3-21. End Play in Wormshaft

(5)

Side play. Side play is the looseness or lateral movement, which is found in improperly fitted or worn

bearing parts, such as the male and female conical bearing surfaces. Such movement should be

reduced to an absolute minimum since it affects not only total backlash but also the proper setting of

level vials attached to the instrument.

(6)

Backlash due to binding. This form of backlash occurs in screw type adjustments which depend upon

steady spring pressure or retaining rings to eliminate lost motion or slack.

(7)

Reduction of backlash (fig. 3-15). On worm and worm gear mechanisms, backlash may be reduced by

tightening the socket against the wormshaft ball. Backlash may sometimes be reduced by replacing the

plunger spring. In cases of emergency only, the spring may be shimmed. Backlash may be eliminated

by removing irregularities from the plunger which might prevent its movement or by filing away, or

relieving, the shaft housing if the shaft bears against it. Bottoming of the worm may be eliminated by

turning off a small amount of metal from the worm, worm gear, or both.

3-18

|