|

| |

TM 9-254

4-15.

Stripping Insulated Wire - Continued

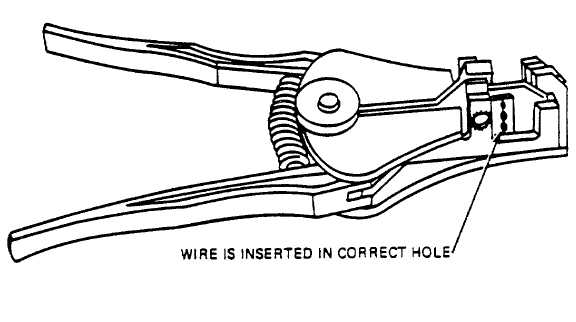

Select the correct hole size to cut the insulation being careful not to nick, break or flair any wire strands. Test the selected

hole size on a piece of wire of the same type and size as the actual wire being used.

Figure 4-32. Mechanical Wire Strippers

4-16.

Tinning Wire.

Before a wire can be soldered to a connection it must first be tinned (pre-soldered). Tinning a wire will help the wire retain

its original configuration and improve its mechanical strength. To properly tin a wire:

(1)

Inspect the wire center conductor or strands for any nicks or broken strands. If any are found, cut off the

center conductor and re-strip the insulation as described in paragraph 4-15.

(2)

Twist stranded wire in the original direction of the individual strands to restore the rounded contour to the

wire.

NOTE

Heat shunts are available in standard sizes. Always use the appropriate size heat shunt according

to the size of the wire being tinned.

(3)

Clean the exposed center conductor (fig. 4-33) with alcohol and allow to dry. Apply a thin coat of flux to

the center conductor before tinning.

4-38

|