|

| |

TM 5-4210-233-14&P-1

5-43. FORWARD TANDEM AXLE AND DRIVE UNIT-Continued

(61)

Check and adjust end play of input

bearings (33 and 50). Place a wood

block between ring gear (19) and case

to keep ring gear (19) from turning.

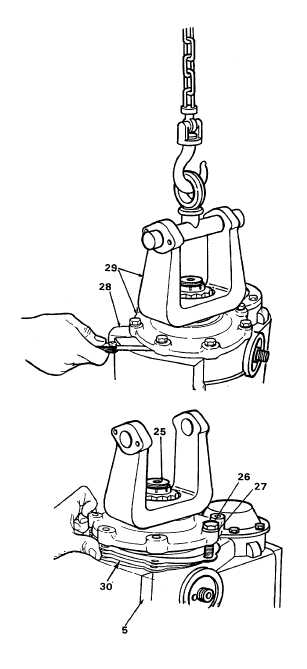

(a) Install seven screws (26) but not

washers (27) to fasten input bearing

cage to carrier. Rotate input shaft (25)

in each direction to make sure bearings

are correctly installed while tightening

screws (27) by hand.

(b) Use a feeler gauge to measure gap

between bearing cage (28) and

differential carrier housing (5). Check

gap at four equidistant places on cage.

(c) Add up the four measurements and

divide by four to arrive at the average

gap. Add 0.005 inch (0.13 mm) to the

average to determine size of shim

pack (30).

(d) Use at least three shims (30) to build a

shim pack (30). Install the thickest

shims in the middle of the shim pack.

(e) Remove the seven screws (26) used to

temporarily fasten bearing cage (28) to

differential carrier housing (5). Connect

a lifting device to input yoke. Lift input

shaft assembly (29) until there is a

distance of 0.25 to 0.50 inch (6 to 12

mm) between cage (25) and differential

carrier (51) mounting surface.

(f)

Install shim pack (30) under bearing

cage (25). Make sure installation

pattern of shim pack matches

installation pattern of cage.

(g) Lower the input shaft assembly (29)

into position over differential carrier

housing (5). Remove lifting device.

Install washers (27) and screws (26)

and torque screws to 75 to 95 lb ft (100

to 130 N•m) while rotating the input

shaft (25) in each direction to make

sure the input bearings (33 and 50) are

correctly installed.

5-317

|