|

| |

TM 5-4210-233-14&P-1

5-7. DRIVE SHAFTS, UNIVERSAL JOINTS AND YOKES

This task covers:

a.

Removal of Drive Shafts

e.

Cleaning and Inspection

b. Inspection of Drive Shafts

f.

Installation of Universal Joints

c. Installation of Drive Shafts

g.

Follow-on Maintenance

d. Removal of Universal Joints

TOOLS REQUIRED

MATERIALS/PARTS REQUIRED

Tool Kit, General Mechanics, Automotive

Penetrating Oil (Item 8, Appendix E)

(Appendix B, Section III, Item 1)

High Temperature Grease (Item 15, Appendix E)

Dry Cleaning Solvent (Item 3, Appendix E)

Shop Equipment, Automotive

Lint Free Cloth (Item 42, Appendix E)

Maintenance and Repair

(Appendix B, Section III, Item 4)

EQUIPMENT CONDITION

Main Engine Shutdown (see para 2-12.)

APU Shutdown (see para 2-16.)

Batteries Disconnected (see para 4-114.)

a.

Removal of Drive Shafts.

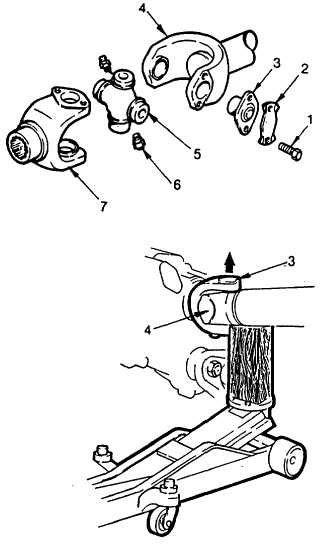

(1) If the drive shaft universal joint locking

screws and straps are corroded, apply

penetrating oil (Item 8, Appendix E) to ease

disassembly.

(2) Mark all yokes and slip joints before

removal. This will ensure alignment of

components during installation.

(3) Using a hammer and chisel bend down the

ears on the two lockstraps (2) attached to

the yoke opposite the drive shaft to be

removed.

(4) Remove capscrews (1) and lockstraps (2).

(5) Turn the yoke until the bearing plates (3) are

vertically aligned. If necessary, raise the

front or rear axle.

(6) Using a floor jack and a block of wood, jack

the wooden block up until it contacts the

drive shaft end yoke (4) as shown.

(7) Continue to jack the block up until it forces

the upper bearing plate (3) out of the yoke.

(8) Once the upper bearing plate has been

removed, lower the jack and rotate the shaft

a half turn. Remove the second bearing

plate similar to steps 5, 6, and 7.

5-28

|