|

| |

TM 5-4210-233-14&P-1

5-80. APU VALVES

This task covers:

a.

Adjustment

b.

Follow-on Maintenance

TOOLS REQUIRED

EQUIPMENT CONDITION

Tool Kit, General Mechanics, Automotive

Rocker Arm Cover Removed (see para 5-72.)

(Appendix B, Section III, Item 1)

a.

Adjustment.

NOTE

Check valve clearance when the engine is at room temperature,

about 70 deg. F (21 deg. C).

(1)

Turn the flywheel until the cylinder is on its

compression stroke. Use a socket wrench on the

flywheel screw.

NOTE

To determine if the cylinder is in its compression stroke, observe

the action of the push rod as the engine is rotated in a clockwise

direction. The exhaust valve push rod will be in its lowest

position and the intake valve push rod will be moving downward.

As the piston reaches top dead center, the flywheel timing mark

should be aligned with the timing pointer and the valve push

rods stationary.

(2)

Now turn the flywheel clockwise for an additional 10 to

45 degrees. There is no timing mark for this position, so

it must be estimated. With the piston located in this

position, it will be in its power stroke with both valves

completely closed.

(3)

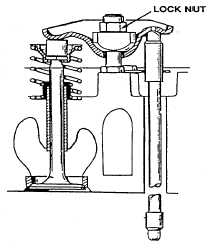

Cylinder head bolt torques should be 44-46 lb ft (60-62

N-m). To change the valve clearance, adjust the locknut

which secures the rocker arm to the cylinder head.

Loosen the locknut to increase clearance and tighten it

to reduce clearance.

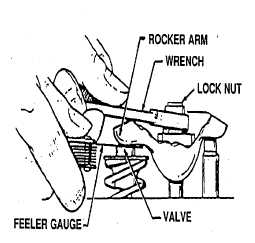

(4)

Check valve clearance with a feeler gauge between the

rocker arm and the valve. Increase or reduce the

clearance until the proper gap is established. Correct

valve clearance is 0.01 1-inch (0.28 mm) intake and

0.008-inch (0.20 mm) exhaust.

b.

Follow-on Maintenance.

(1)

Install rocker arm cover (see para 5-72).

5-406

|