|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-233-14&P-1

5-70. APU CAMSHAFT, GEAR AND BEARINGS - Continued

b. Inspection.

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard's solvent)

is potentially dangerous. Avoid repeated and prolonged

breathing of vapors and skin contact with the liquid. Do not

use near open flame, arcing equipment or other ignition

sources. Always wear eye protection and protective clothing.

The flash point of P-D-680 is 100 to 138 deg. F (38 to 59

deg. C).

Death or serious injury could occur if compressed air is

directed against the skin. Do not use compressed air for

cleaning or drying unless the pressure is/has been reduced

to 30 psi (2.1 1 kg/cm?) or less. When working with

compressed air always use chip guards, eye protection, and

other personal protective equipment.

(1) Clean camshaft exterior with dry cleaning solvent (Item 3, Appendix E) and dry using compressed air,

inspect for damage.

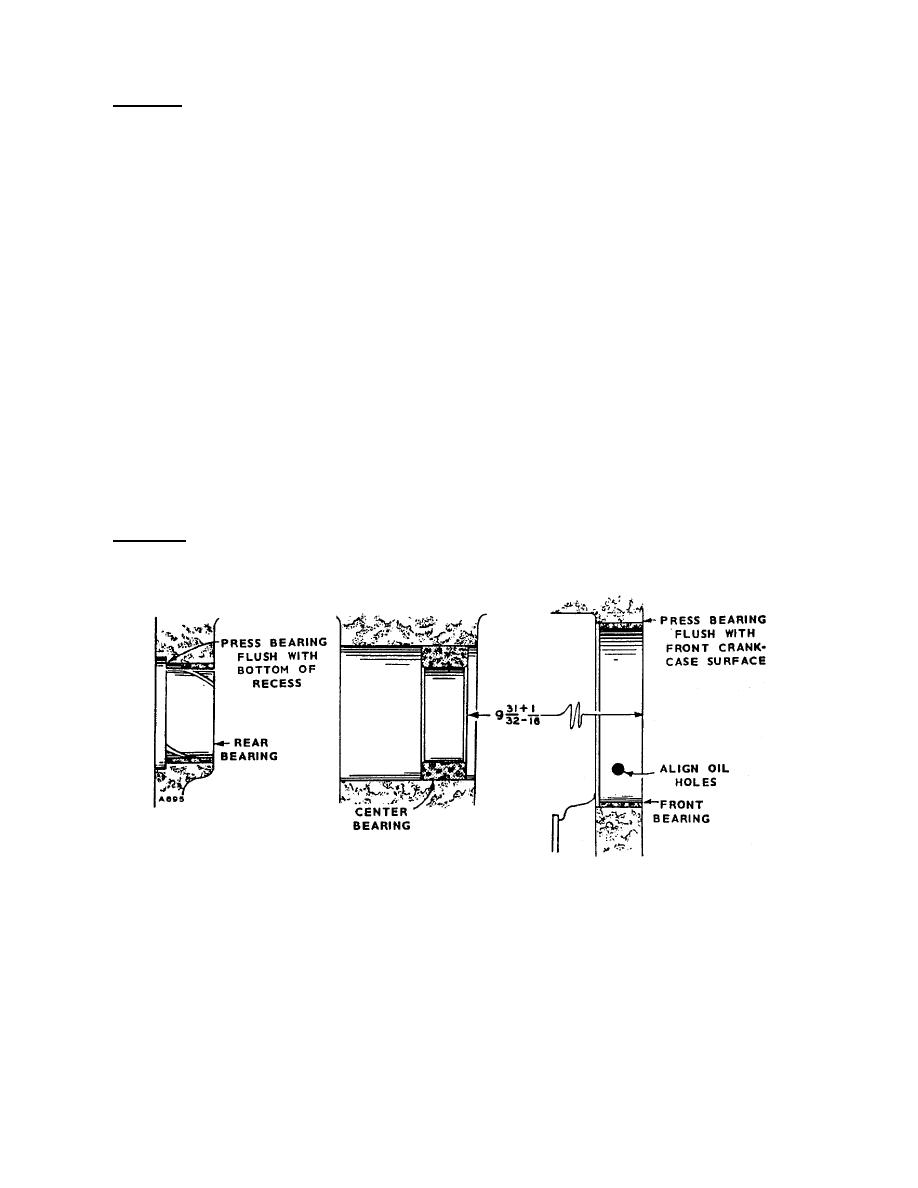

(2) Clean and inspect front, center, and rear camshaft bearings. If bearings show cracks, breaks, burrs, or

excessive wear, they must be replaced. Camshaft-to-bearing clearance should be .0012 to .0037 in.

(.030 to .094 mm). To check rear camshaft bearing, remove expansion plug at rear of crankcase.

c.

Installation.

(1) Press new bearings (if required) into place as shown.

5-377

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |