|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-233-14&P-1

5-66. APU GENERATOR-Continued

e. Testing/Repair.

NOTE

Testing of Generator consists of continuity checks using wiring

diagram (Appendix F).

NOTE

Most of the following tests can be performed without

disassembling the generator. Clearly mark all leads dis-

connected, together with the point taken from.

(1) Armature. Remove all brushes from their holders.

(2) Using ohmmeter, check for continuity in the ac winding for an open circuit between the slip rings. If

an open circuit is found, replace the armature.

(3) Test both the slip rings and commutator for short or grounding to he shaft.

t

(4) To test the armature for an open circuit in the dc windings 'O" reading indicates open circuit. Check

continuity between all adjacent bars of the commutator. Visually inspect for bar burring, arcing and

poor cranking.

(5) Touch the probes to two adjacent bars and check for continuity. Move each probe over one bar and

check again. Continue around the commutator. Any adjacent bars that don't show continuity

indicate an open armature winding.

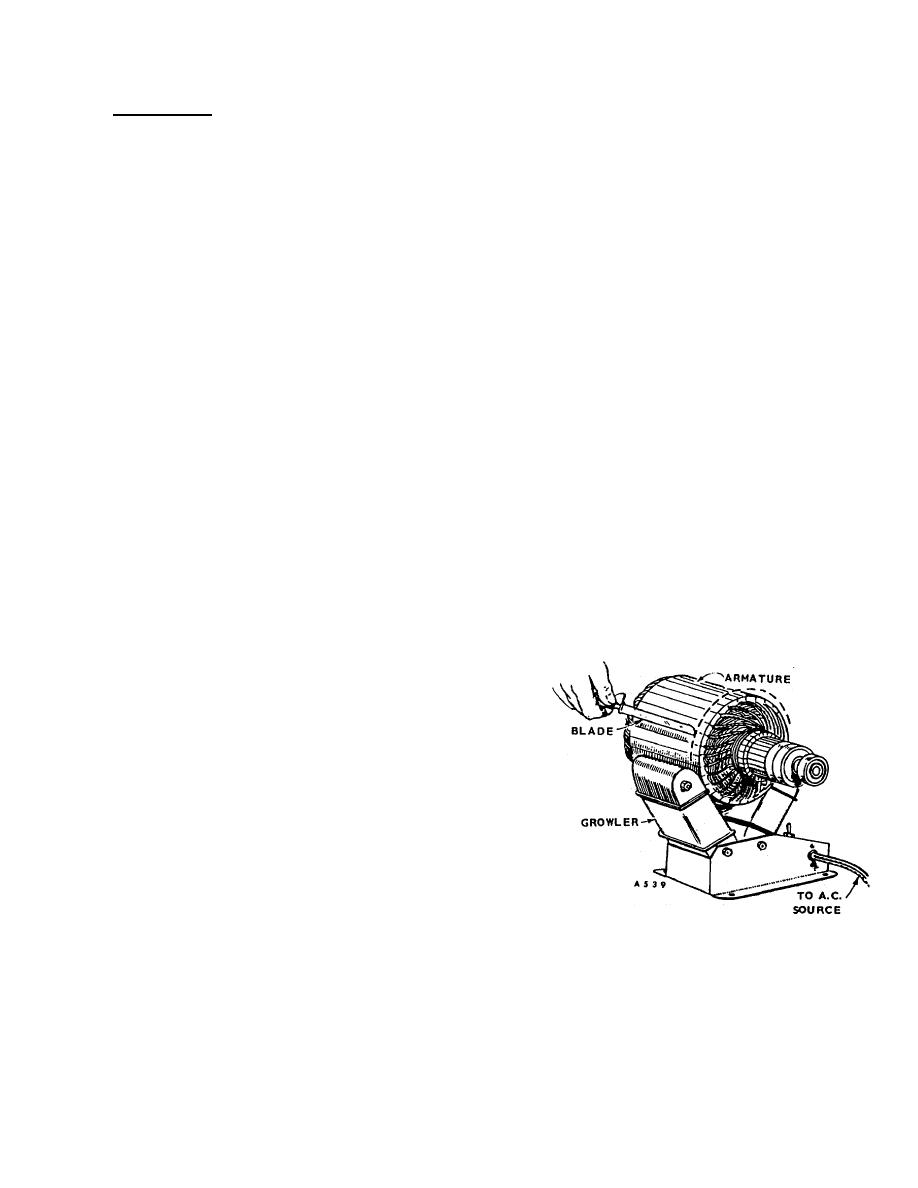

(6) This test can only be performed with the g nerator disassembled and requires a growler. To test for

e

shorts in the dc winding, place the armature in the growler. Operate the growler and pass a steel

strip back and forth over and above the armature windings. If the strip is magnetically attracted to

the armature at any point, a short is indicated. After testing in one position, rotate the armature

slightly and repeat the test. Do this for one complete revolution.

(7) If the test indicates a short circuit in the

dc windings, be sure the commutator is

clean.

Carbon dust, dirt or grease

between the bars or slip rings can cause

a short.

(8) If the tests show that the armature is

defective, replace it.

(9)

Field Winding Tests: The following

tests can be performed without

disassembling the generator, but the

field coil leads must all be

disconnected from their terminal points;

brush rig, control box, and external

connections. If a defective coil is

found, disassemble the generator and

replace the defective coil.

(10) With an ohmmeter or continuity lamp, check for grounding to the generator frame. Touch one prod

to the coil terminals and the other to a clean, paint-free part of the frame. If grounding is indicated,

separate the windings and check each one.

5-367

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |