|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-233-14&P-1

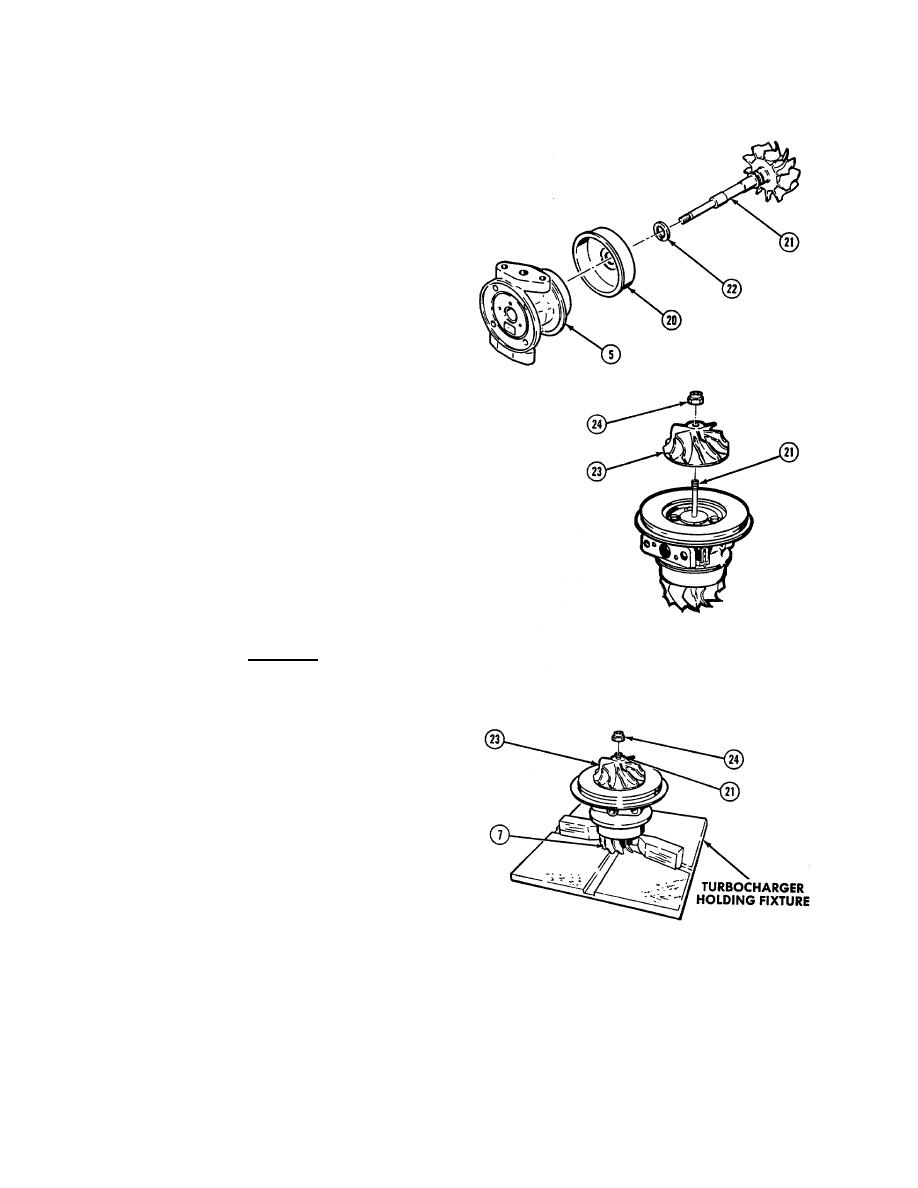

5-23. TURBOCHARGER-Continued

(11) Install turbine shroud wheel (20) on

center housing (5).

(12) Fill piston ring groove with Dow

Corning High Vacuum Silicon grease

or equivalent (Item 11, Appendix E)

and install piston ring (22) in groove.

(13) Install turbine wheel shaft (21)

through the shroud wheel and into

center housing (5) Lubricate the

wheel shaft bearing surfaces with oil

(Item 10, Appendix E) prior to

assembly.

(14) Install compressor wheel (23) on shaft (21).

(15) Lubricate shaft threads and wheel face

surface that will be under the nut with oil

(Item 10, Appendix E), and install locknut

(24) on shaft (21).

(16) Place turbine wheel (7) in holding fixture.

CAUTION

Do not put a bending load on shaft

while tightening locknut use a

double universal socket and tee

handle wrench.

(17) Tighten locknut (24) to 125-150 lb in

(14 to 17 Nm).

(18) Loosen locknut (24).

(19) Inspect faces of locknut (24) and

compressor wheel (23) Make sure

both surfaces are clean and smooth.

(20) Apply lubricating oil to threads of shaft

(21) and base of locknut (24).

(21) Retighten locknut (24) to 35 to 55 lb in

(4 to 6 Nm).

5-156

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |