|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-233-14&P-1

5-22.

BLOWER REPAIR - Continued

(3) Check the oil seal rings, carriers and collar for wear or scoring. If worn excessively, they must be

replaced. The current oil seal rings are chrome flashed and the carriers are liquid nitrided. When

replacement of an oil seal ring or carrier is neccessary, both parts must be replaced together.

(4) Inspect the inside surface of the blower housing for burrs or scoring. The inside surface must be

smooth for efficient operation of the blower. If the inside s rface of the housing is slightly scored or

u

burred, it may be cleaned up with emery cloth (Item 25, Appendix E).

(5) Examine the rotor shaft serrations for wear, burrs or peening. Also inspect the bearing and oil seal

contact surfaces of the shafts for wear or scoring.

(6) Inspect the inside surface of the blower housing for burrs or scoring. The inside surface must be

smooth for efficient operation of the blower. If the inside surface of the housing is slightly scored or

burred, it may be cleaned up with emery cloth (Item 25, Appendix E).

(7) Check the finished ends of the blower housing for flatness or burrs. The end plates must set flat

against the blower housing. The finished inside face of each end plate must be smooth and flat. If

the finished face is slightly scored or burred, it may be cleaned up with emery cloth (Item 25,

Appendix E).

NOTE

Be careful not to remove metal at the joint face

between the end plates and the housing. Air or oil

leaks could develop after assembly.

(8) Inspect both timing gears at teeth and at bore splines for

chips or nicks.

(9) Inspect oil holes. If clogged, clean with dry cleaning

solvent (Item 3, Appendix E).

c.

Assembly.

NOTE

Do steps (1) through (4) for all four ring carriers.

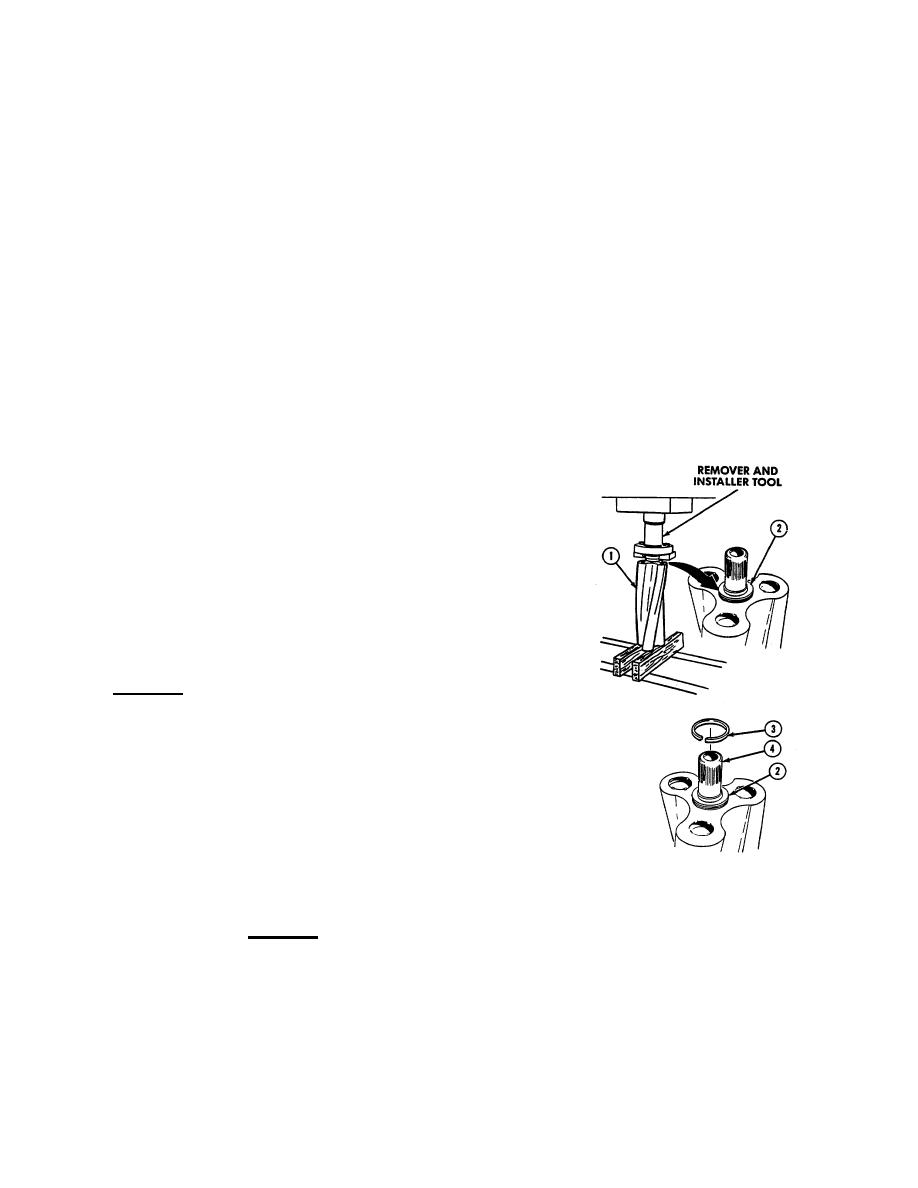

(1) Support rotor (1) on blocks.

(2) Apply lubricating oil (Item 10, Appendix E) inside ring

carrier (2).

(3) Install ring carrier (2) tight to rotor (1) with large side

facing rotor using remover and installer tool.

CAUTION

Do not spread oil seal rings too much when install-

ing or rings will break.

5-130

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |