|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

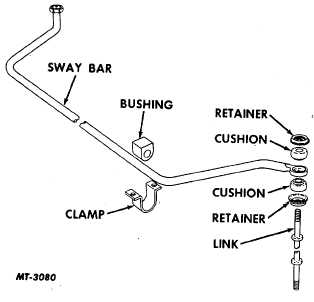

Fig. 7 Front Sway Bar

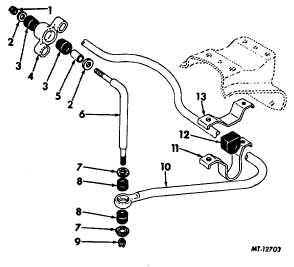

Fig. 8. Rear Sway Bar

Legend for Fig. 8

Key

Description

1

NUT

2

WASHER

3

BUSHING

4

BRACKET

5

SPACER

6

LINK, Sway Bar

7

RETAINER, Cushion

8

CUSHION

9

NUT

10

SWAY BAR

11

BRACKET

12

BUSHING

13

BRACKET

Sway bars are available for both front (Fig. 7) and

rear (Fig. 8) suspension applications.

Simple in construction, these bars perform their

stabilizing effect by twisting when spring height at

opposite wheels becomes unequal. For example, if the

wheel on one side drops into a chuck hole, the spring on

that same side expands. At the same time the sway bar

tends to expand the opposite spring and lift the truck.

Failing to do this, the bar twists and lessens the shock of

the wheel dropping.

In like manner, if the wheel on one side hits an

obstacle, the spring on that side compresses. The sway

bar tends to compress the opposite spring and hold the

truck down. Failing to do this, the sway bar twists and

lessens the shock. This resistance to twisting in the

sway bar is particularly useful in limiting sway or roll

when the truck is rounding a curve or when it suddenly

encounters a strong cross wind.

No service is necessary on the sway bar other

than a periodic inspection to see that mounting parts

remain secure. Rubber bushings should be replaced

when they become deteriorated or permit metal to metal

contact. Keep mounting bolts tight.

CTS-2680S Chapter I Page 6

PRINTED IN UNITED STATES OF AMERICA

|