|

| |

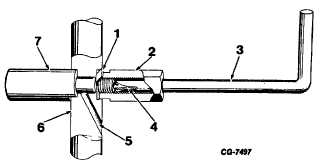

Figure 57. Adjusting Governor Using Tool SE-2072-2

1.

Lock

5.

Vertical Hole

2.

Counterweight

6.

Distributor Shaft

3.

Adjusting Tool

7.

Governor Valve Body

4.

Screw (Tang)

8. Reinstall governor clamp and gasket assembly.

9. Reinstall governor seal.

10. On distributors so equipped, be sure the governor spinner

valve air cleaner is cleaned or replaced at regular intervals

depending on severity of operation.

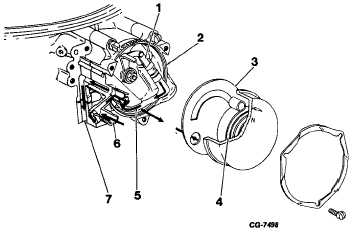

Automatic Choke

The automatic choke assembly consists of a

bimetallic thermostat spring and vacuum piston. The

automatic choke assembly is mounted on the carburetor main

body. A passage through the main body connects the

vacuum system to the manifold area. When the engine is

cold, the bimetal spring closes the choke plate for starting.

When the engine starts, manifold vacuum is applied to the

choke piston through a passage in the main body and with the

help of air flow on the offset choke plate, opens the choke

against the tension of the bimetal spring.

A heat stove is installed in the exhaust manifold and

an asbestos-covered tube connects the heat stove to the

choke housing. As the engine is warmed up, hot air is

circulated to the choke housing to warm up the bimetal spring.

As the spring warms up, its tension will be released on the

choke shaft and allow it to open gradually. The warm air then

passes through a hole in the choke piston and down the

passage in the main body to the manifold vacuum passage.

A choke lever is provided on the side of the carburetor which

actuates a fast idle cam during choking. The fast idle cam

has a series of stops on one side which are designed to

increase the engine idle RPM for smoother running when the

Figure 58. Automatic Choke Assembly

1. Piston and Lever

5. Vacuum Passage

Assembly

6. From Heat Tube

2. Choke Housing

7. Vacuum Passage

3. Choke Housing Plate

4. Thermostat Spring

engine is cold. As the engine is warmed up and the choke opens,

each step on the fast idle cam permits the engine to run at a

slower RPM.

An adjustable piston stop screw controls the initial travel

of the choke piston. The piston, in turn, controls the initial opening

of the choke plate or choke qualifying dimensions. To check the

choke qualifying dimension, follow the procedure outlined below:

1.

Bend a paper clip as shown in insert in Fig. 59).

2.

Place bent end of clip on top of piston and depress

piston until it bottoms on stop screw (Fig. 59).

3.

Rotate choke lever tang counterclockwise until

choke piston link touches top of piston (Fig. 59).

4.

Measure clearance on lower edge of choke plate at

inner wall of air horn. See SPECIFICATIONS for

correct setting.

5.

Adjust clearance by moving adjusting screw in or

out.

6.

After adjustment has been established, seal off

head of adjusting screw with sealing compound.

A small unloader lever is provided on the throttle shaft

which will manually open the choke plate when the throttle lever is

at the wide open position. This permits the operator to relieve an

over

choke

condition.

To

overcome

a

flooded

CGES-125-T Page 39

PRINTED IN UNITED STATES OF AMERICA

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ADJUSTMENT PROCEDURE

|