|

| |

TRUCK GROUP SERVICE MANUAL

TM 5-4210-230-14&P-1

GENERAL

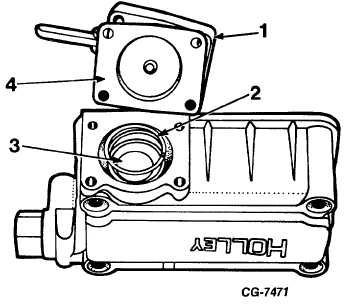

Figure 15 Acceleration Pump Assembly (shown with plastic

pump inlet valve used on later model carburetors).

1. Diaphragm Cover

3. Plastic Valve

2. Diaphragm Return

4. Diaphragm Assembly

Spring

diaphragm. Hydraulic pressure forces fuel in the pump cavity

and channels past the needle check valve and out the pump

discharge nozzles into the air stream.

Upon return of the throttle lever toward idle position, the

diaphragm spring returns the diaphragm and the resultant

pressure differential causes the discharge valve to close and the

inlet ball or plastic check valve to open, allowing the pump

cavity to refill with fuel from the bowl.

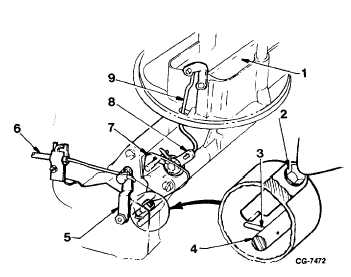

Choke System

The function of the choke system is to provide a rich

air/fuel mixture necessary for cold starting and engine warm-up

(Fig. 16).

The choke plate, which is manually operated on governor

type carburetors, may be closed during the engine cranking

period and partially opened during the warm-up period. This

induces a low pressure on the fuel metering system, causing

both the main and idle systems to discharge more fuel

producing mixtures rich enough to insure smooth power as the

engine warms up.

During the full choke period, the high point of the fast idle

cam is in contact with the fast idle adjusting screw which sets

the throttle plates at a predetermined angle causing engineRPM

to be high upon starting. As the choke is manually opened,

Figure 16 Manual Choke System

1. Choke Plate

6. Choke Cable

2. Fast Idle Adjusting Screw 7. Fast Idle Cam

3. Fast Idle Pin

8. Choke Rod Lever

4. Throttle Shaft

9. Choke Rod

5. Choke Lever

the cam moves rotationally away from the fast idle adjusting

screw allowing the engine to resume its normal idle speed

setting.

Throttle Modulator-1970-1971 Vehicles Under 6000 Lbs.

GVW

To provide acceptable exhaust emission levels, the

carburetors of certain vehicles require the use of a throttle

modulator.

The throttle modulator is vacuum operated and functions

above a predetermined road speed to aid in the control of

exhaust emission during engine deceleration.

Fig. 17 shows throttle modulator diagram. A speed

sensor (spinner valve) is driven by the speedometer cable. A

vacuum source and bleed line are piped into the speed sensor.

The sensor is designed to open the bleed line to the vacuum

source when vehicle road speed is below the predetermined

cutoff speed (approximately 24 MPH). As long as the bleed line

is open, no vacuum is available to extend the modulator.

When the vehicle passes the road speed cutoff point, the

bleed line is closed, making vacuum available to actuate the

modulator.

CGES-125-T Page 10

PRINTED IN UNITED STATES OF AMERICA

|