|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

Apply the same procedure to the remaining bearing caps.

Recheck the crankshaft end play as outlined under

"Fitting Main Bearings."

8.

Install flywheel housing on crankcase. Torque bolts to

specified torque. See "Torque Chart." Install oil pressure

sending unit.

9.

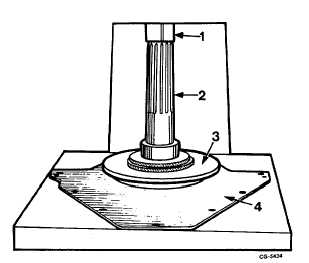

Press crankshaft rear oil seal into retainer plate using SE-

1905 installer and 5-1/4" O.D. adapter, Figure 142. The

seal must be installed from the crankcase side of the

retainer flush with the seal bore inner surface.

Fig. 142 Pressing Rear Oil Seal into Retaining Plate Using SE-

1905 Installer with 5-1/4" O.D. Adapter

1. Press ram

3. Adapter

2. Installer

4. Retainer

NOTE: Wipe inside of retainer plate clean to insure a

proper fit.

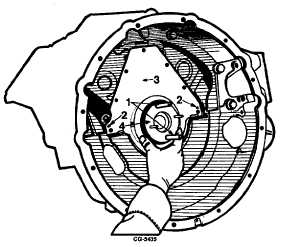

10. Use SE-1942-2 Pilot to install rear oil seal and retainer

with gasket on crankcase, Figure 143. Dowel pins are

provided for proper alignment. Torque bolts to specified

torque. See "Torque Chart."

NOTE: Drill two 25/64" diameter holes in SE-1942-2 Pilot

according to the dimensions on Figure 144 to accept two

3/8" diameter x 4" pilot studs. The pilot studs serve as a

safety measure to retain the pilot on the crankshaft where

seal replacement is performed with engine in the vehicle.

Fig. 143 Installing Retainer with Rear Oil Seal Using

SE-1942-2 Pilot

1. Pilot studs

3. Retainer

2. Dowel pins

4. Pilot

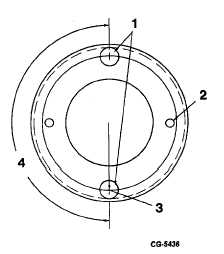

Fig. 144 Dimensions for Rework of SE-1942-2 Pilot

1. 25/64" dia. holes

2. Existing guide pin holes

3. 1.59375R

4. 180°

11. Rotate the crankshaft and camshaft to determine that the

gears do not bind or interfere. With the use of a dial

indicator, Figure 145, check the backlash. See

"Specifications" for backlash.

CGES-210 Page 58

PRINTED IN UNITED STATES OF AMERICA

|