|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

After

removing

the

plunger,

the

check

valve

assembly may be found to be loose on the plunger. Care

should be taken so the small, flat check valve and valve

retainer spring are not lost. If the check valve assembly stays

attached to the plunger, it would be best to leave it in this

position.

IV.

Servicing the Lifter

The following is the service procedure to be followed in

servicing hydraulic lifters:

A

Immerse the unit in carburetor or other suitable

solvent to remove excess engine oil and soften

varnish deposits.

B.

To avoid mixing plungers and cylinders, take one

lifter apart at a time and complete all servicing before

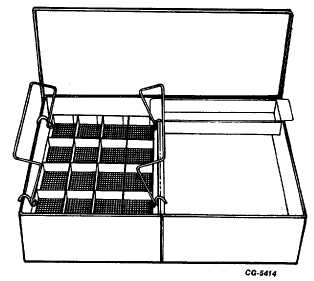

working on another. However, if tray SE-1892,

Figure 121, is available for keeping plungers and

cylinders

together,

all

lifters

may

then

be

disassembled at the same time.

Fig. 121 Hydraulic Lifter Tray SE-1892

C.

Wash all parts in solvent and clean all varnish from

the plunger and inside diameter of the cylinder.

D.

Inspect the plunger and cylinder walls for scratches.

Look for nicks on the valve seat and examine the

condition of the lifter face. Check for plugged oil

holes.

E.

Try the plunger for free fit in the cylinder. F.

Reassemble all parts in proper sequence Figure 120.

NOTE:

The valve lifter body is to be filled 1/3 full

with clean kerosene before assembly of

component parts. The parts are to be

prelubricated with clean kerosene before

assembly. Use of kerosene in place of

engine oils provides a faster leakdown and

rapid expelling of trapped air in the lifter

assembly, thus eliminating the possibility

of damage to the valve train when

installing the push rods and rocker arm

shaft assembly. Engine oil will dilute the

kerosene in the lifters as soon as the

engine is operated for a short period.

G.

After the unit has been washed thoroughly, determine

whether the leakage past the plunger and cylinder is

correct and if the check valve is functioning correctly.

This may be done using one of the two following

methods:

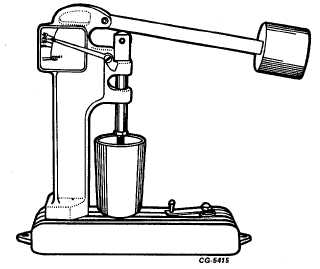

1. The SE-1893 leakdown tester, Figure 122, may be

used for checking the leakdown rate if available.

Instructions which accompany the tester should be

followed.

Fig. 122 SE-1893 Tester Used for Checking Leakdown Rate

of Tappet

2.

If the leakdown tester is not available, a finger check

method can be used. In order to check a unit in this

manner, make sure there is no lubricating oil on the

cylinder or plunger such as immediately after

washing in solvent. With the cylinder held in one

hand, start the

CGES-210 Page 47

PRINTED IN UNITED STATES OF AMERICA

|