|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

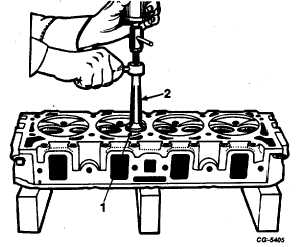

Inspect the exhaust valve seat inserts for looseness,

burned or cracked condition. Use SE-1951 valve insert

remover, Figure 111, to remove defective inserts. Position the

remover collet into the insert and turn the coned screw out to

expand the collet jaws, thus providing a firm grip under the

insert ring. Use a slide hammer to remove the insert.

Fig. 111 Pulling Exhaust Valve Insert with SE-1951 Remover

1.

Exhaust valve insert

2.

Valve insert

remover

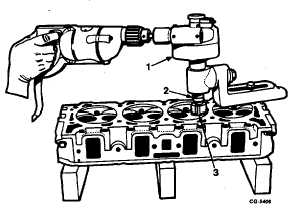

Prior to seat reconditioning, it is desirable to clean

the seats in order to expose any cracks or other conditions

likely to promote valve failure. Such inspection is particularly

important in engines equipped with hard seat inserts; cracked

or loose inserts are not uncommon and are usually caused by

improper installation. Good practice requires that the insert

counterbore in the cylinder head be machined prior to insert

installation, Figure 112. Cutters are available to dress both

the bottom and circumferential surfaces, but regardless of the

method, the bottom of the counterbore must be square to

assure good seating of the insert.

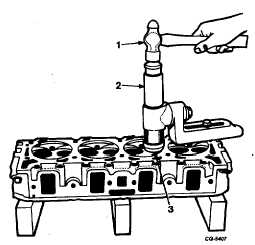

Before installing inserts they should be thoroughly

chilled with dry ice or other means to facilitate their installation

in the cylinder head. Use the installer tool, Figure 113, from

the counterbore tool set'SE-1797. Valve seat inserts supplied

for service are standard size, .015" oversize and .030"

oversize.

Fig. 112

1.

Cutter drive unit

2.

Drive shaft

3.

Cutter

Fig. 113 Using Insert Installer from Counterbore Tool Set SE-

1797 for Installing Inserts in Cylinder Head

1.

Hammer

3.

Seat

2.

Driver

The valve seats "A" and "B" in the cylinder head,

Figure 114, must also be ground true to the angles and width

shown in the specifications section. If the seat is wider than

specified, it

CGES-210 Page 41

PRINTED IN UNITED STATES OF AMERICA

|