|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

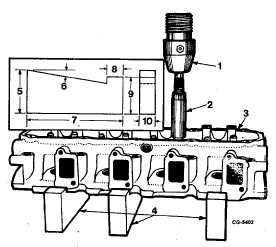

Remove all guides that exceed wear limitations using

SE-1722 valve guide remover. All guides must be driven from

the combustion chamber side through the top of the head as

shown in Figure 107.

NOTE:

Support blocks used for removing valve

guides should be 9" long x 3-5/8" high x 1-

5/8" thick rectangular hardwood blocks.

These blocks should not be used for

installation of valve guides.

Turn the cylinder head over with the top side up on

the wood support blocks positioned in the press. Install the

valve guides from the top side of the cylinder head using SE-

1943 valve guide installer, Figure 109. The tool is designed to

install both valve guides. This can be accomplished by

adjusting the installer screw in the body to a depth that is

equivalent to the specified height that guides are to be

installed above the head. Figure 109 illustrates the method to

be used when adjusting the installer for specified guide height.

Press the guides in until the installer rests firmly on top of the

cylinder head, thus maintaining proper spacing.

NOTE:

Guides

should

be

lubricated

with

a

mixture of light engine oil and white lead

upon installation. Clean away any excess

lubricants.

Fig. 108 Installing Valve Guides with SE-1943 Installer and

Adaptor

1.

Press m

6.

9°

2.

Installer

7.

9"

3.

Cylinder head

8.

11/2

4.

Support Blocks

9.

31/2"

5.

4 1/8

10. 11/2"

NOTE:

Support blocks for installing valve guides

can be made locally to the dimensions

shown in the insert on Figure 108.

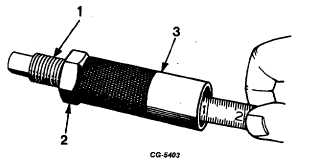

Fig. 109 Adjusting Valve Guide Installer SE-1943 for Proper

Height

1.

Adjusting screw

3. Body

2.

Locknut

After guides are installed, insert SE-2215 reamer in

the guides to see that they have not been distorted during

installation and to remove any burrs.

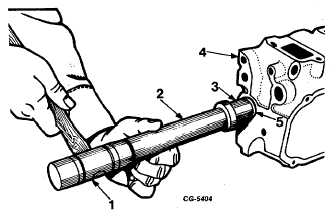

Cylinder head core plugs should not be disturbed

unless evidence of leakage exists. Remove and install plugs

as inspection warrants. The plugs can be removed by drilling

a small hole in the center of the plug and with a suitable pry or

screwdriver, remove the plug from its bore. To install a new

plug, coat the outer edge with a suitable nonhardening sealing

compound and with installer SE1945 and driving handle SE-

1581-lB, install plug flush with bottom edge of chamfer in

cylinder head, Figure 110.

Fig. 110 Installing Cylinder Head Core Plugs Using Installer

SE-1945 and Driver Handle SE-1581-1B

1.

Hammer

4.

Cylinder head

2.

Driver handle

5.

Core plug

3.

Installer

CGES-210 Page 40

PRINTED IN UNITED STATES OF AMERICA

|