|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

surfaces for scratches or mars which could cause leakage

after assembly. The use of holding fixture SE-1939 reduces

the chances of gasket surface damage.

Check the gasket surface of the cylinder head for

trueness with a straightedge. Test by attempting to insert a

.003" feeler gauge ribbon between the straightedge and

cylinder head. If this is possible, either resurface or replace

the cylinder head.

NOTE:

When resurfacing the cylinder head, do

not remove more than .005" material.

Cylinder head height measurement should

be taken between the machined surface of

the head and the machined surface of the

bolt bosses on the exhaust manifold side

of the head. The original specification for

this measurement is 3.282" + .010".

The cylinder head assemblies and head gaskets are

interchangeable from one cylinder bank to another.

To disassemble the valve assembly, turn the head

assembly in a vertical position either on a clean work bench or

using SE-1939 cylinder head holding fixture as a cradle to

hold the assembly.

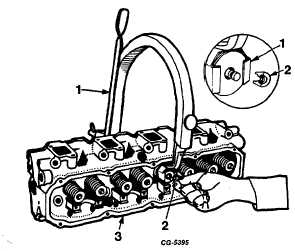

Apply a valve spring compressor and remove the

valve keepers or locks, Figure 102. Remove the spring

compressor and disassemble the spring retainer, valve stem

seal and Roto-Coil assembly from the exhaust valves.

Remove the spring retainer, valve stem damper, spring, valve

stem seal and valve spring seat from the intake valves. All

valves are removed in

Fig. 102 Removing Valve Keepers

1.

Valve spring compressor

2.

Keepers

3.

Cylinder head

the same manner. Keep valves and their related parts

together so they may be reinstalled. in their respective

positions.

NOTE:

It may be necessary to strike the valve

ends with a light, soft hammer to break the

valve keepers loose.

Remove all carbon from valve stems and head using

a fine wire brush or buffing wheel. Inspect each valve,

discarding any that show evidence of burned, warped or bent

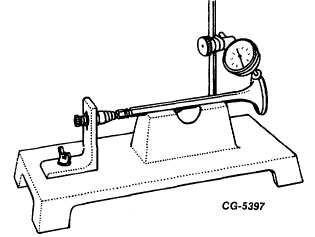

condition. SE-2614 valve gauge, Figure 103, or similar tool

can be used for checking stem straightness and seat run-out.

Fig. 103 Checking Valve Stem Straightness and Face Run-

Out

Fig. 104 Checking Spring Tension Using SE-2241 Tester

CGES-210 Page 38

PRINTED IN UNITED STATES OF AMERICA

|