|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

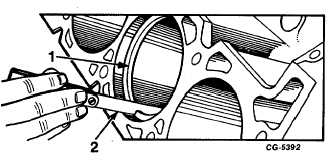

is square with the cylinder wall. Check the space or gap

between the ends of the ring with a feeler gauge, Figure 99.

See specifications for proper ring gap.

NOTE:

Extreme care should be taken during this

operation.

Fig. 99 Checking Ring Gap

1.

Piston ring

2.

Feeler Gauge

If the gap on the compression rings is less than the

limit, try the next size smaller ring. Each ring should be fitted

and checked in the cylinder in which it is to be used and

marked accordingly.

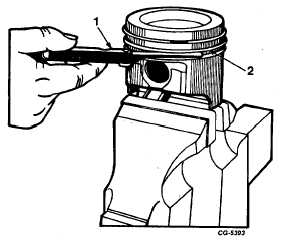

Piston rings should be checked for side clearance in

the groove of the piston on which they are to be installed.

This is done by placing the outer edge of the ring in the piston

groove, rolling the ring entirely around the piston to make sure

the ring is free in the groove. With a feeler gauge check the

side clearance

Fig. 100 Checking Ring-to-Groove Side Clearance with Feeler

Gauge

1.

Feeler Gauge

2.

Piston ring

of each ring in its respective groove, Figure 100. See

specifications for proper clearance.

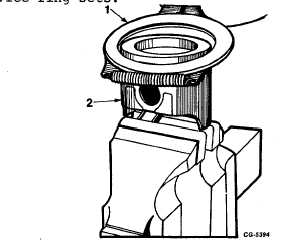

Assemble the rings on the pistons to which they were

fitted by using a piston suitable ring expander tool. This type

of tool is recommended to avoid over-expanding and also to

expand the ring to a true circle to avoid distortion, Figure 101.

General practice is to stagger the ring gaps when installing

piston rings. For further information refer to the instructions

furnished with the service ring sets.

Fig. 101 Installing Piston Ring Using Suitable Piston Ring

Expander Tool

1.

Piston ring expander

2.

Piston

Cylinder Heads, Valves, Valve Guides, Springs, Etc.

The cylinder heads, as removed from the engine,

contain the valve mechanism. The rocker arms were removed

prior to removing the heads. Position the cylinder head on the

intake manifold surface on a clean work bench or install the

cylinder head in holding fixture SE-1939 to protect the

machined

surfaces

during

cleaning

and

disassembly

operations.

With the valves installed to protect the seats, clean

the carbon deposits from the combustion chambers and valve

heads with a wire brush and scraper. Wash the heads in

cleaning solvent to remove dirt and grease from all surfaces

and dry thoroughly. Check all water passages to make sure

they are clear and open.

Examine the cylinder heads for water leaks or cracks

in the combustion chambers, exhaust ports and around the

valve seats. Inspect the machined or gasket

CGES-210 Page 37

PRINTED IN UNITED STATES OF AMERICA

|