|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

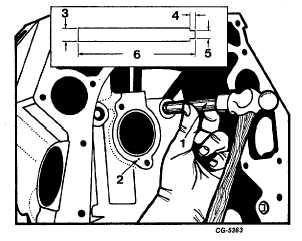

Remove the tappet oil gallery plugs by drilling a small hole in

the plug and prying with a screwdriver or suitable tool. Clean

the tappet oil galleries with SE-2334-1 Brush (5/16" diameter).

Replace the tappet gallery plugs flush to .060" below

crankcase surface using tool shown in Figure 70. The tool

may be made locally from cold rolled steel to the dimensions

shown in Figure 70.

Fig. 70 Tappet Oil Gallery Plug Installation

1. Installer tool

4. .200

2. Oil hole

5. .410

3. .490

6. .450

NOTE: Coat the edges of the plugs with a

suitable nonhardening sealing compound prior to

installation.

If it becomes necessary to remove an expansion type

plug due to water leaks, drill a 1/2" hole in the center of the

plug and remove by prying with a screwdriver or suitable tool.

When installing the expansion plug, the concave side of the

plug must be installed on the interior of the cylinder block.

Coat the edges of #he plug with a suitable nonhardening

sealing compound and install using a 1" diameter brass drift

and hammer.

Inspection of the cylinder block should be done

carefully to detect any scoring of the cylinder bores, cracks or

water leaks. Small cracks may be found by coating the

suspected areas with a mixture of light motor oil and

kerosene. After wiping the area dry, immediately apply a coat

of quick drying liquid such as zinc oxide powder mixed with

wood alcohol. Wherever cracks are present, a brown

discoloration will appear in the white coating.

Check the top surface of the cylinder block for trueness

with a straightedge. Test by attempting to insert a .006" feeler

gauge ribbon between the straightedge and cylinder block

. If

this is possible, replace the cylinder block.

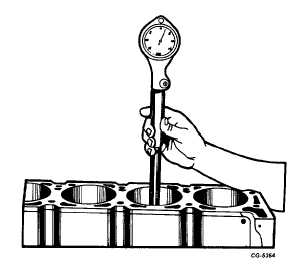

Each cylinder bore should be checked with an inside

reading micrometer SE686 or dial bore gauge SE-2331 to

determine taper, out-of-round or worn condition, Figure 71.

Measure the diameter of the cylinder bore at the top of the

piston ring travel at right angle "A", Figure 72, to the centerline

of the crankshaft. Record the readings. Next, measure each

bore so the gauge reading coincides with the centerline "B",

Figure 72, of crankshaft. The difference between "A" reading

and "B" reading is the out-of-round condition at the top of the

cylinder bore. Repeat the same procedure at the bottom of

the ring travel to check for out-of-round. The difference

between the diameters measured at the top "A" and the

bottom "B", Figure 73, of the bore (at right angles to centerline

of the crankshaft) is the taper of the bore.

Fig. 71 Checking Cylinder Bore Using Dial bore Gauge

SE-2331

CGES-210 Page 26

PRINTED IN UNITED STATES OF AMERICA

|